The Application Of The Air Dunnage Bag

In logistics transportation, how to ensure the safe arrival of goods to the destination is always the focus of enterprises and consumers. Traditional packaging materials such as foam and pearl cotton are gradually being replaced by more efficient and environmentally friendly solutions, while logistics inflatable bags have become a star product in the field of modern packaging with their unique performance and flexible applications.

Logistics inflatable bag is a packaging material that uses air as a buffer medium, absorbs the impact force through an independent air column or air cushion structure, and provides 360-degree protection for the goods. Its application scenarios are wide:

1. E-commerce and express delivery: protect glass products, electronic products, ceramics and other fragile products to reduce the rate of transportation damage.

2. Industrial transportation: used to fill gaps in containers to prevent goods from shifting or colliding during long-distance transportation.

3. High-value goods: such as precision instruments, luxury goods, etc., through customized air column bag design to achieve personal protection.

4. Environmental protection needs: Some air column bags are made of degradable materials, in line with the trend of green packaging.

Inflatable bags can save up to 50% of storage space compared to traditional materials and reduce material waste while enhancing brand image.

The Introduction For The Air Dunnage Bag

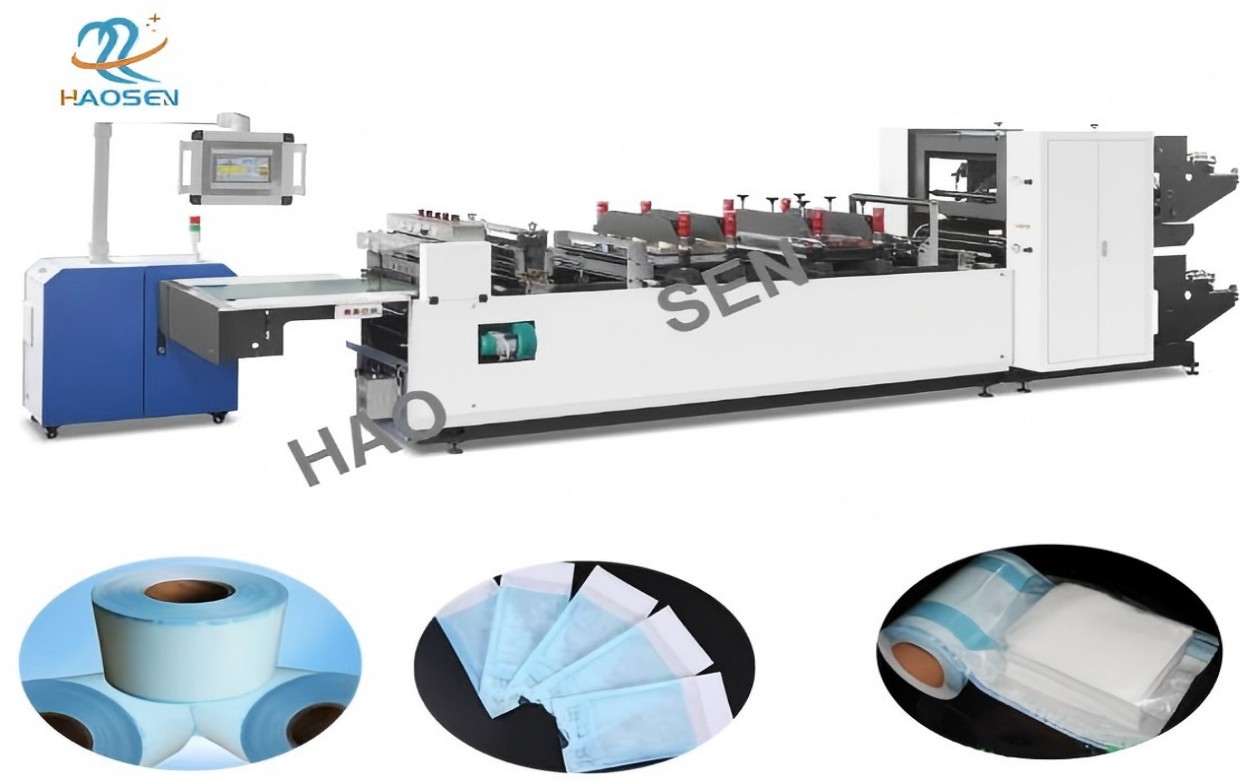

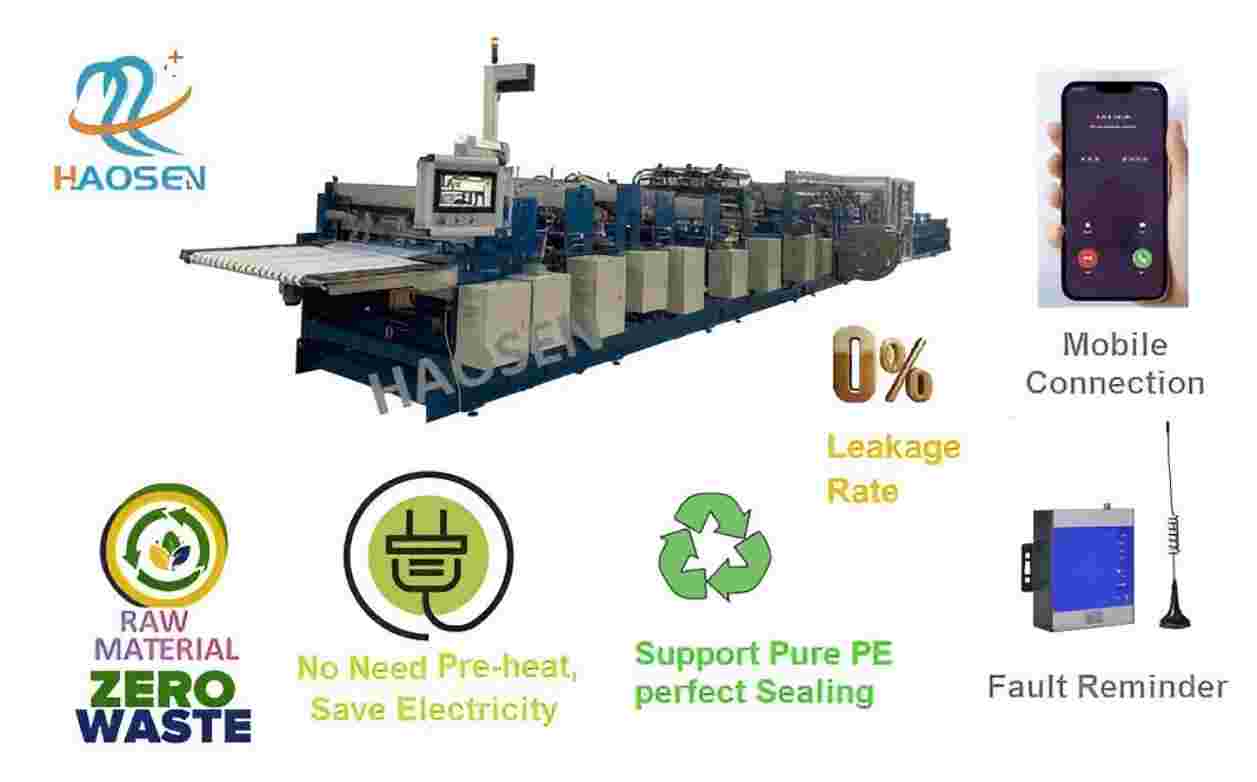

The air dunnage bag consists of outer bag, inner bag,valves and label(optional). To use air dunnage bags, we also need inflatable tools.

There are two kinds inflatable tools used in different situations as following chart.

|

No.

|

Picture

|

Application

|

|

1

|

|

In conventional scenarios, it is convenient to use the buckle on the air valve and the switch to inflate

|

|

2

|

|

It can be used in scenes with narrow gaps

|

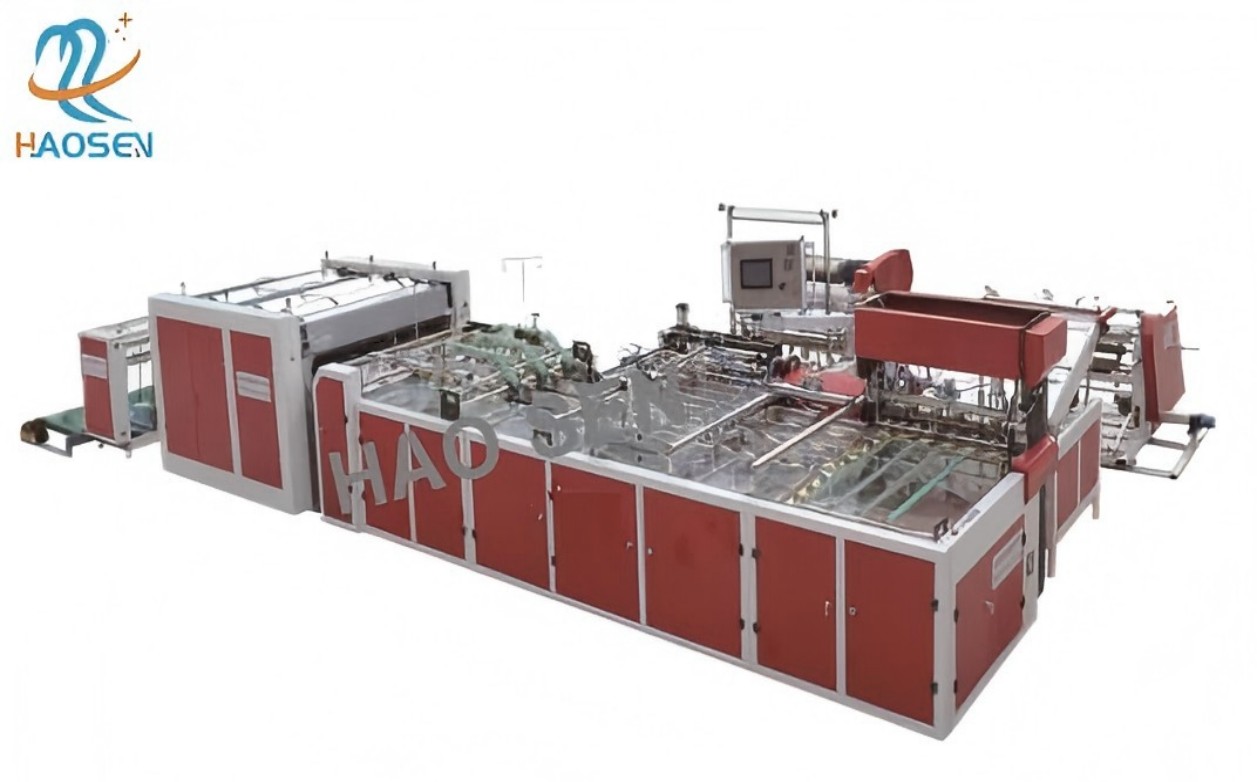

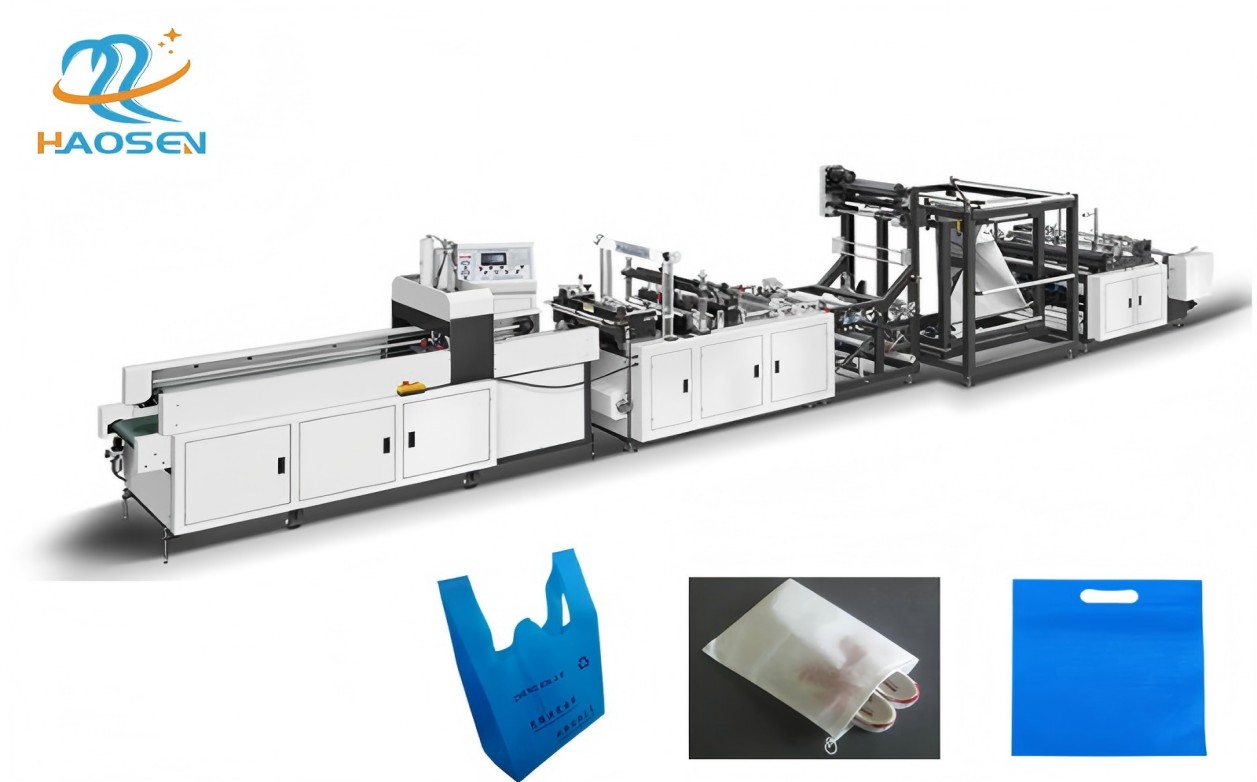

The first step is to cut outer bag to needed length.(The suitable materials for outer bag are PP woven fabric tubular rolls PP woven fabric and kraft paper

The second step is to punch a hole on the outer bag.

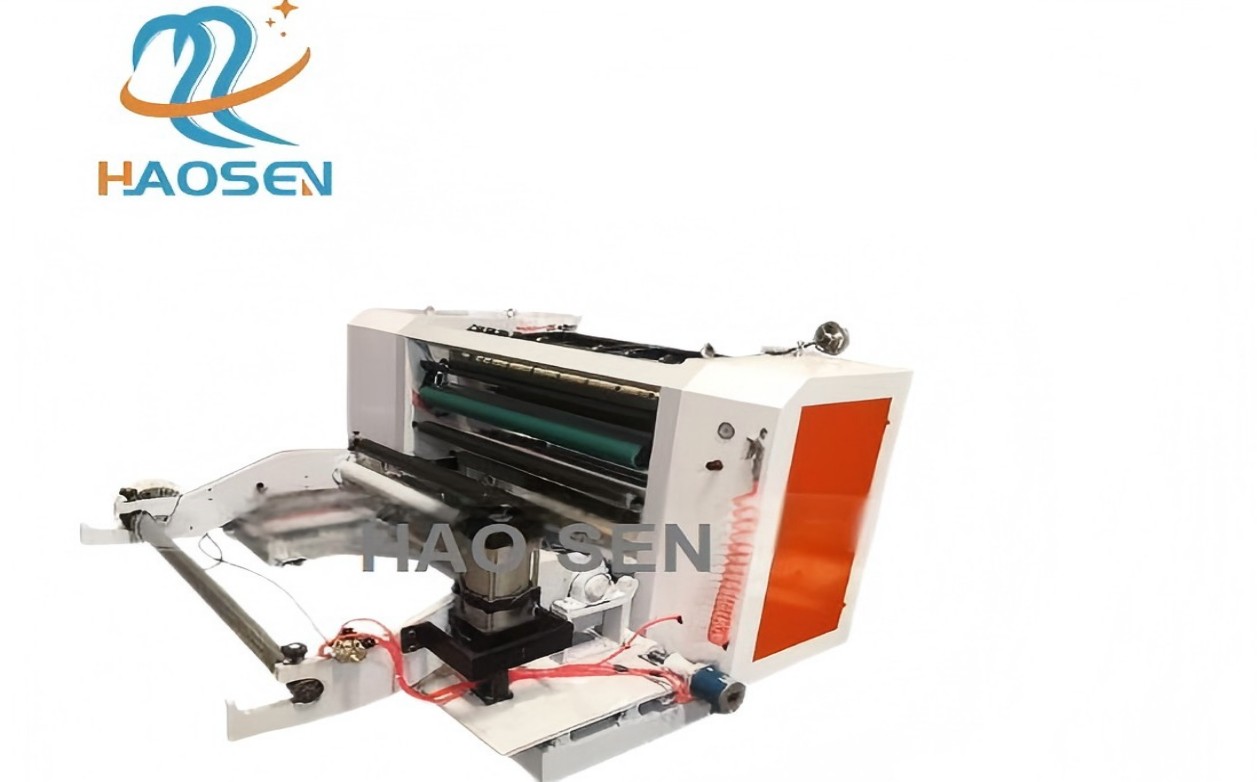

The third step is to produce inner bags by automatic inner bag making machine.(The suitable material for the inner bag is PA&PE co-extrusion film )

The fourth step is to put the inner bag to outer bag manually.

The fifth step is to put the ring and the label manually.

The last step is to sew the double sides.

The Usual Size For The Air Dunnage Bag

|

No.

|

Size

|

No.

|

Size

|

|

1

|

400*800

|

19

|

1000*1000

|

|

2

|

400*1800

|

20

|

1000*1200

|

|

3

|

500*500

|

21

|

1000*1300

|

|

4

|

500*600

|

22

|

1000*1500

|

|

5

|

500*900

|

23

|

1000*1600

|

|

6

|

500*1200

|

24

|

1000*1800

|

|

7

|

600*1000

|

25

|

1000*1900

|

|

8

|

600*1200

|

26

|

1000*2000

|

|

9

|

600*1500

|

27

|

1000*2100

|

|

10

|

600*1800

|

28

|

1000*2200

|

|

11

|

800*1000

|

29

|

1200*1200

|

|

12

|

800*1200

|

30

|

1200*1500

|

|

13

|

800*1500

|

31

|

1200*1800

|

|

14

|

800*1600

|

32

|

1200*2000

|

|

15

|

900*1200

|

33

|

1200*2400

|

|

16

|

900*1500

|

34

|

1500*1800

|

|

17

|

900*1650

|

35

|

1500*2000

|

|

18

|

900*1800

|

Remark: The red color represents higher market share

|

Logistics inflatable bag is not only the innovation of packaging materials, but also the balance of logistics efficiency and environmental protection concept. From small e-commerce items to large industrial shipments, its flexibility and reliability are redefining the standard for transportation safety. In the future, with the iteration of technology, this "air shield" will certainly play a more important role in the global supply chain.

For details, contact us via WhatsApp: +86 15633821221

You can learn more from:

https://www.hsbagmachinery.com/air-inflatable-dunnage-liner-bag-making-machine-for-container_p100.html