Production Process of Valve Woven Bags

Valve woven bags are packaging products featuring valve designs based on standard woven bags, offering unique structures and functionalities. They are widely used for packaging powdered and granular materials.

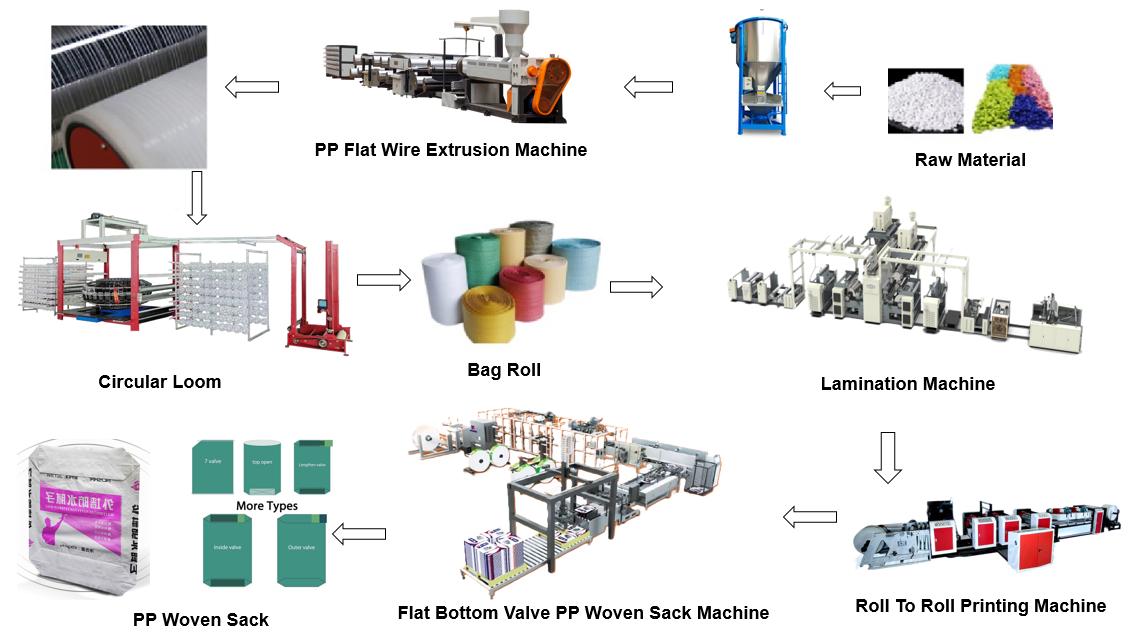

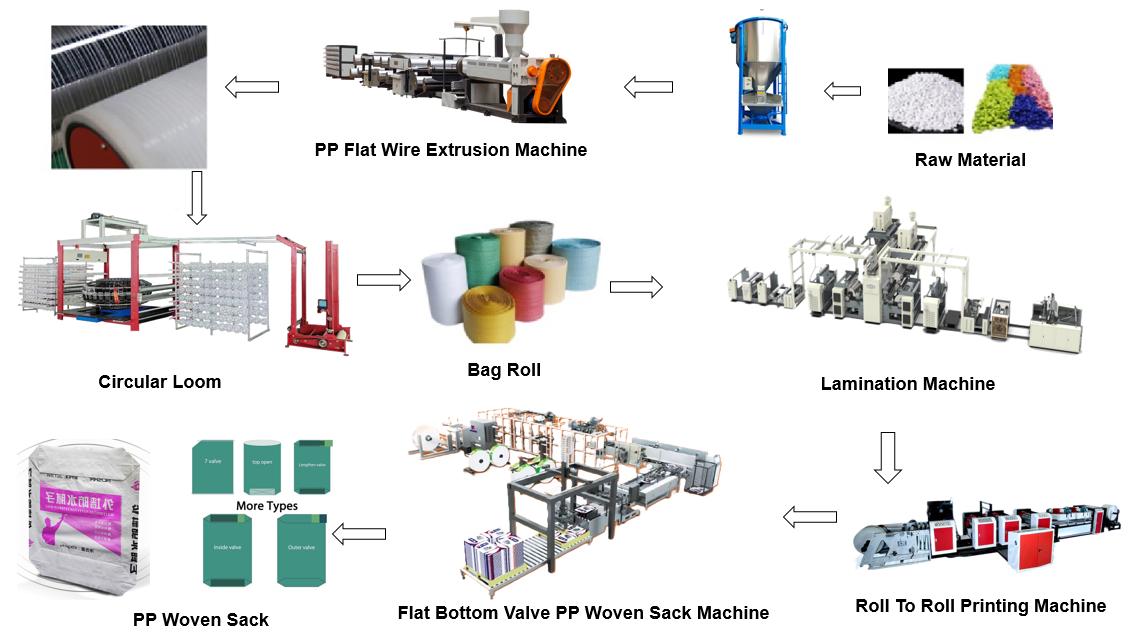

The diagram below illustrates the production flowchart of laminated woven bags:

1. Drying and Mixing Machine: PP plastic granules are fed into a drying mixer for uniform mixing and drying. The drying mixer is connected to the front feed port of the filament drawing machine, directly supplying prepared PP granules to the machine.

2. Flat Wire Extrusion Machine: The PP Flat Wire Extrusion machine melts, extrudes, cools, and shapes the PP granules into PP filaments. At the end of the machine, a filament winder collects the filaments into rolls, forming PP Wire Roll.

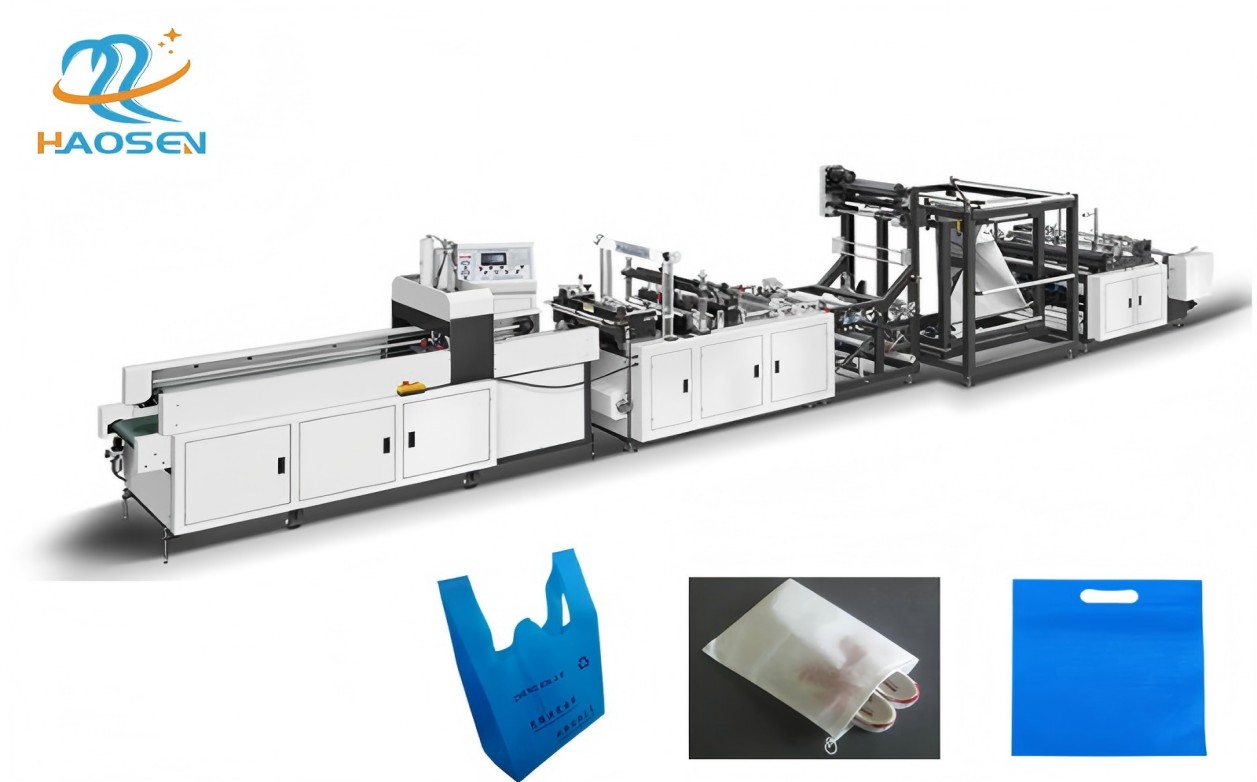

3. Circular Loom Machine: The PP Wire Roll are woven into PP Bag Roll using a Circular Loom Machine.

4. Lamination Machine: The PP Bag Roll are laminated with an outer film via a laminating machine, becoming PP Laminated Bag Rolls.

5. Printing Machine: The PP Laminated Bag Roll are printed with colors using a printing machine, resulting in colored PP Laminated Bag Roll.

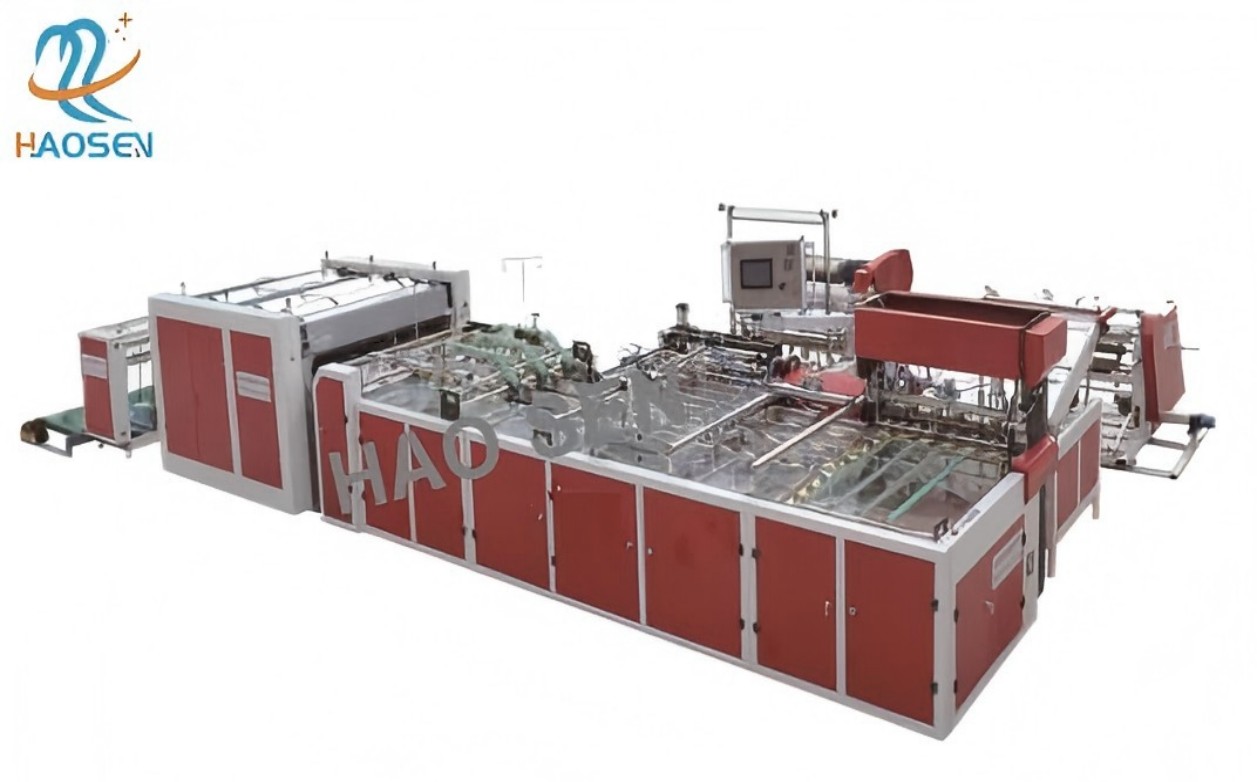

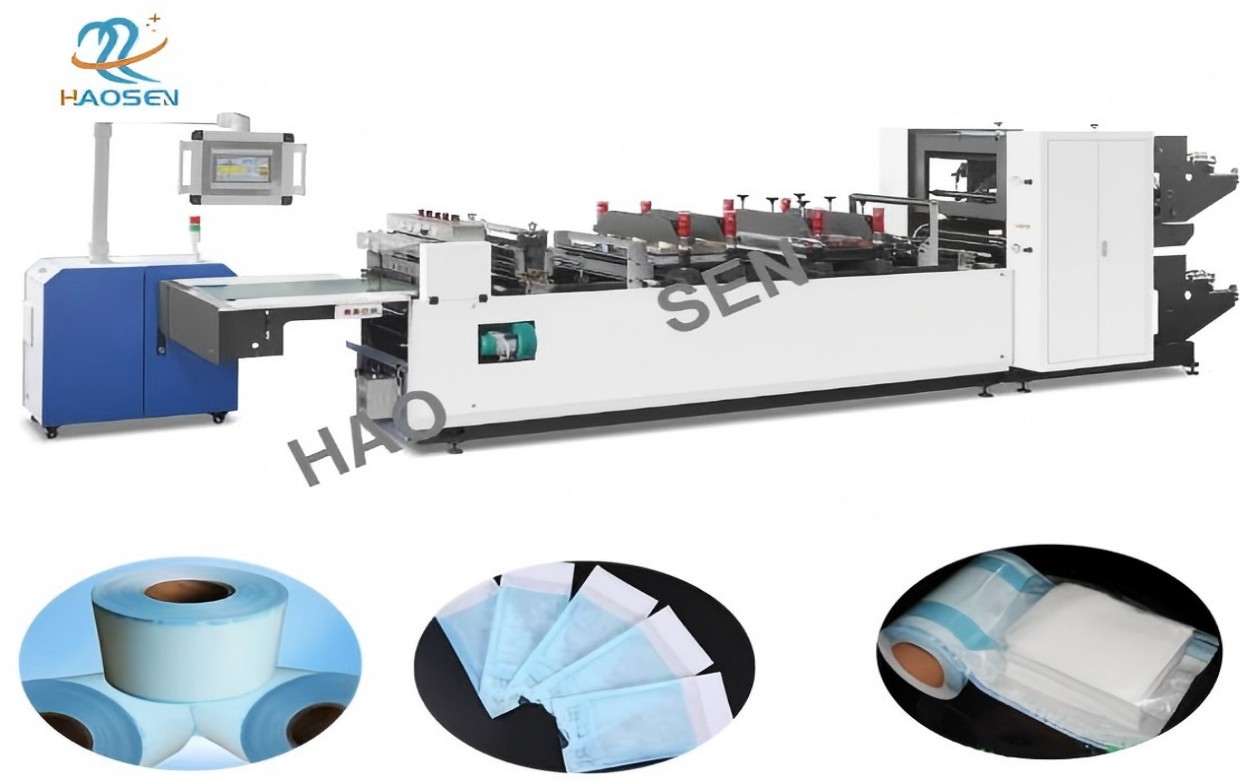

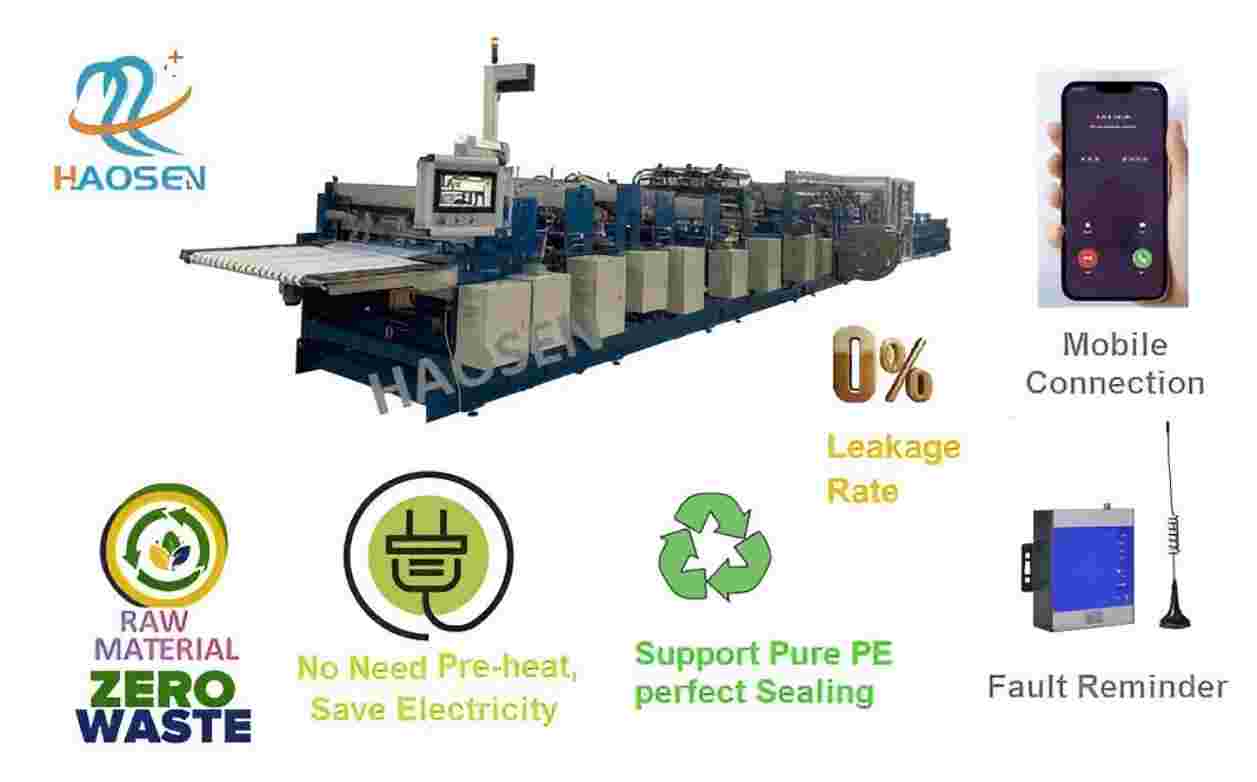

6. Flat Bottom Valve PP Woven Sack Machine: The PP laminated fabric rolls are cut and bottom-reinforced by a block bottom valve sack making machine to produce PP valve sacks.

Application Fields of Valve Woven Bags:

Construction Materials Industry

a) Cement, gypsum powder, putty powder: Valve design prevents dust dispersion and suits mechanized filling.

b) Quartz sand, ceramic raw materials: Moisture-resistant woven bags protect material dryness.

Mining and Metallurgy

a) Mineral powders, metal granules.

Chemical Industry

a) Fertilizers, animal feed, plastic granules: Sealing prevents moisture absorption or volatilization.

b) Hazardous material packaging: Specialized materials (e.g., anti-static, UV-resistant) for chemical raw materials.