-

Valve bag introduction

Valve bag introduction Valve bags are small bulk packaging containers that are convenient, neat, and well sealed. They are one of the most popular packaging forms and a new type of environmentally friendly packaging product, especially suitable for export packaging. When used, they can be fed from the top or bottom valve port, and special filling equipment is used. After filling, the materials are...

-

Production Process of Valve Woven Bags

Production Process of Valve Woven Bags Valve woven bags are packaging products featuring valve designs based on standard woven bags, offering unique structures and functionalities. They are widely used for packaging powdered and granular materials. The diagram below illustrates the production flowchart of laminated woven bags: 1. Drying and Mixing Machine: PP plastic granules are fed into a drying...

-

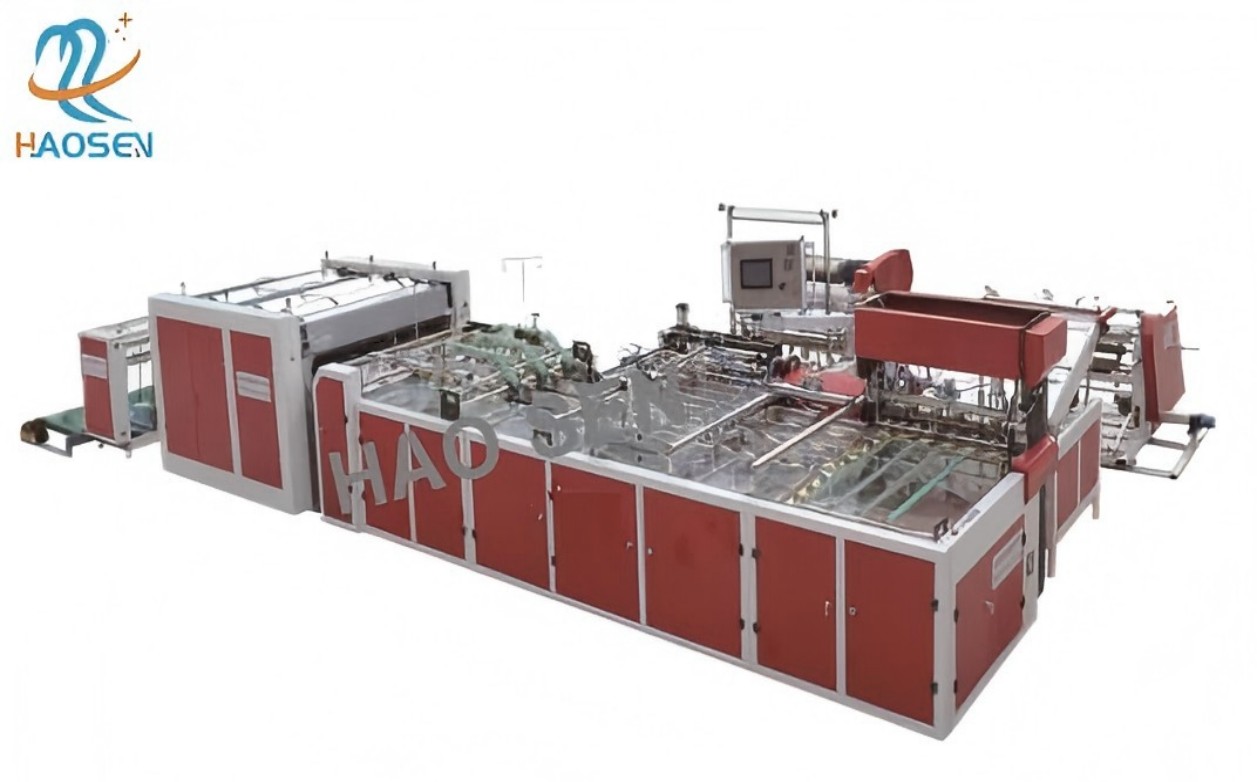

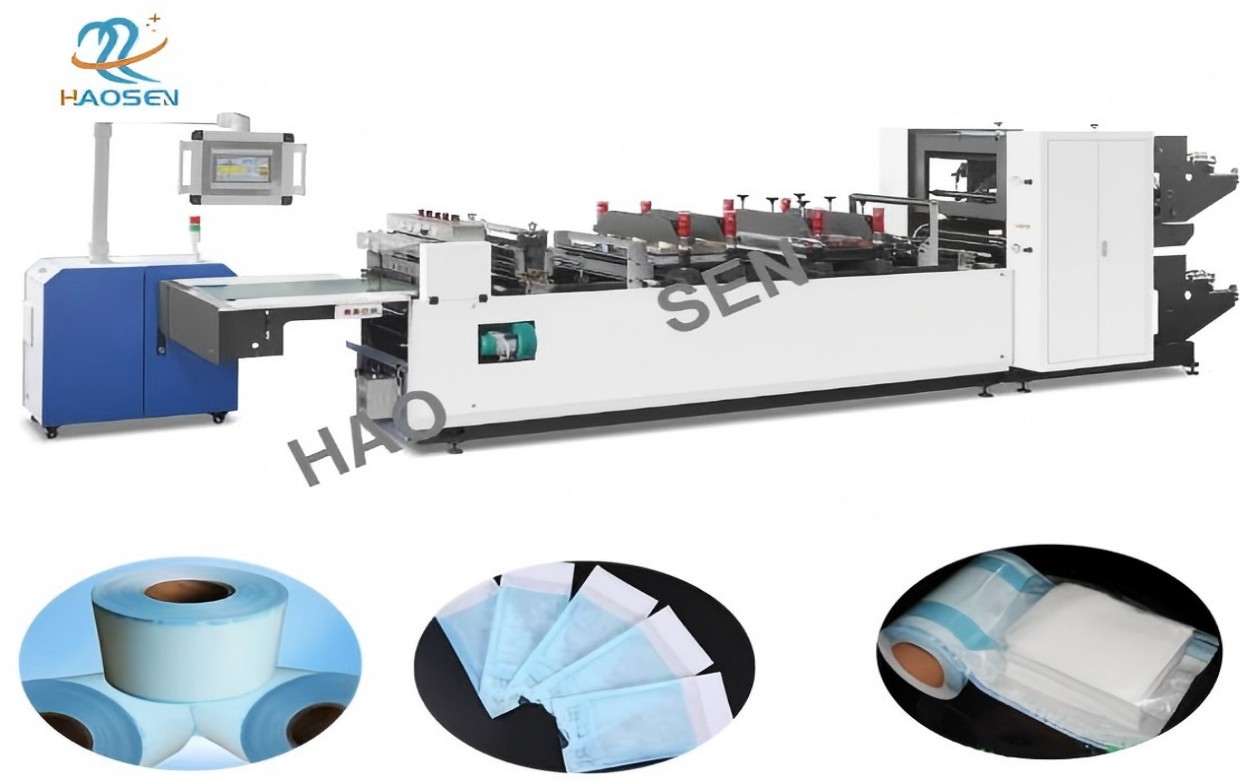

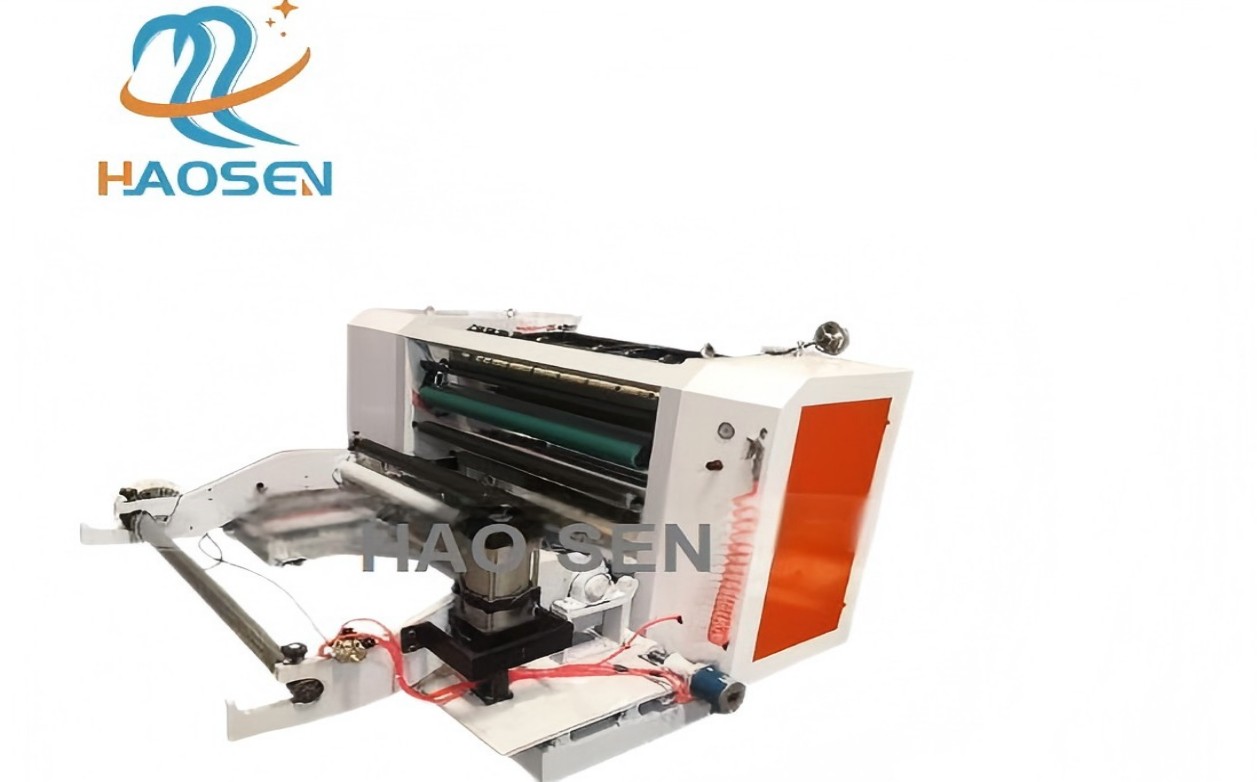

Explanation of the multiple feeding device of BIB/Air dunnage bag inner bag making machine

Explanation of the multiple feeding device of BIB/Air dunnage bag inner bag making machine The production process of the BIB/Air dunnage bag inner bag making machine: two PP/PE films are placed on the loading rack respectively, corrected by the automatic correction system, then punched, valves installed and sealed, and then cut into finished bags by cutting knives after longitudinal and transverse...

-

Production Process of Hemming Inner-Lined Woven Bags

Production Process of Hemming Inner-Lined Woven Bags A woven bag with an Hemming inner liner is a packaging product that adds an inner bag design to the standard woven bag, primarily used for occasions requiring item separation or protection. The bag structure is as follows: Outer layer: Typically woven from polypropylene (PP) or polyethylene (PE), offering features such as wear resistance and ten...

-

Production Process of Laminated Woven Bags

Production Process of Laminated Woven Bags Laminated woven bags are composite packaging materials made by applying a plastic film (e.g., polyethylene PE, polypropylene PP) onto woven fabric through a lamination process. These bags combine the load-bearing strength of woven fabric with the moisture resistance, waterproofing, and dust proof properties of the laminated film. Below is the product...

-

Spout Pouch Making Machine Introduction

Spout Pouch Making Machine Introduction Spout Pouch making machine includes stand up pouch making machine, spout pouch making machine and other auxiliary equipment. This presentation mainly introduces the spout pouch making machine. Our company has three different kinds of machine, which are HSHZD-1800B HSHZD-1800C and HSHZD-1800D. The production process of Model B machine The bag body without the...

-

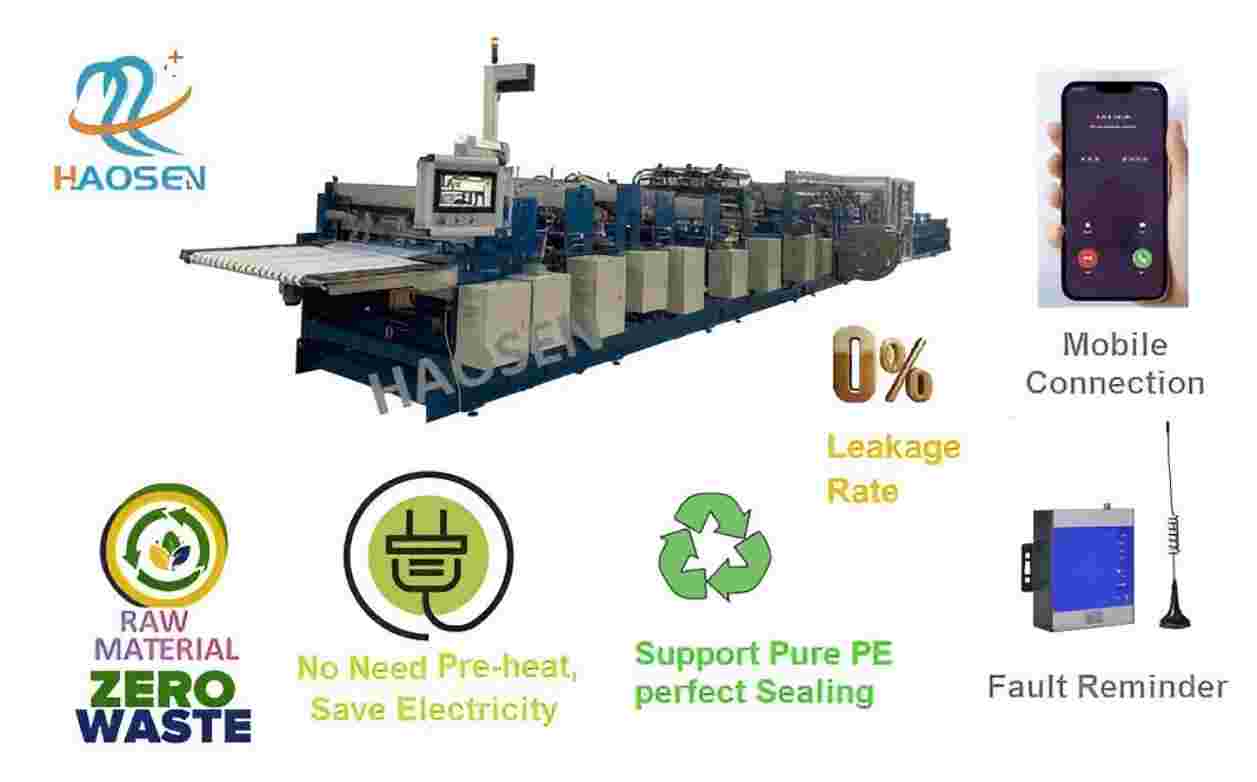

Expansion of Three-side Sealing Bag Making Machine Functions

Expansion of Three-side Sealing Bag Making Machine Functions The three-side sealing bag making machine is a versatile equipment that can produce various types of bags based on the three-side sealing bag. Below is a detailed explanation of its expanded functions: 1. Three-side Sealing Bag: This is the machine's basic function, producing standard three-side sealed bags. 2. Three-side Sealing Stand-u...

-

Spout Pouch Market Analysis

Spout Pouch Market Analysis Market Scenarios: Spout pouches are a novel category of packaging which incorporates a spout for easy use of liquid and semi-liquid products, These pouches can easily be made from various types of flexibles as for instance multilayer laminates of plastics such as PET, PE and in some cases,foil. This also ensures the safety of the contents within them. The spout pouch ma...

-

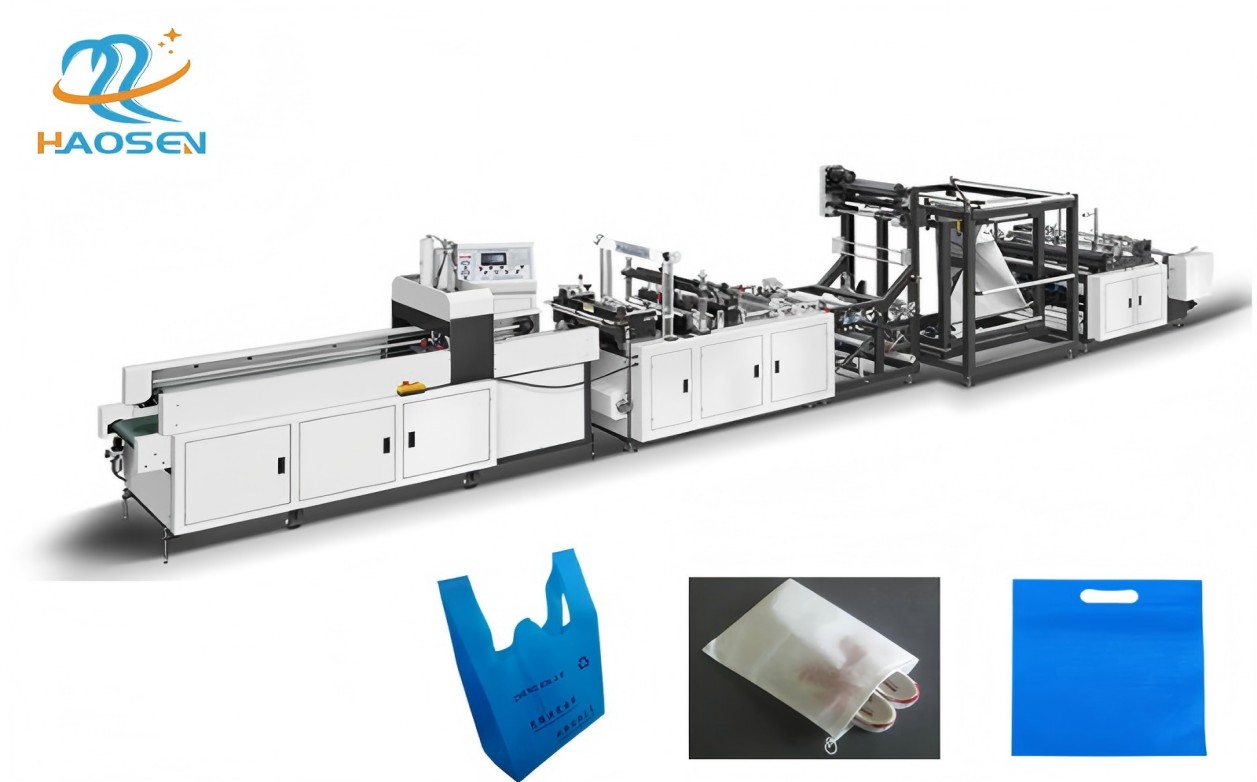

Optional Functions Of OPP/BOPP Bag Making Machine

Optional Functions Of OPP/BOPP Bag Making Machine OPP bags and BOPP bags are common plastic packaging materials, widely used in many industries, resulting in a variety of OPP/BOPP bags. Below I will introduce in detail the functions related to OPP/BOPP bag making machine. 1. Automatic feeding The machine can automatically feed OPP/BOPP film rolls to ensure continuous production. 2. Cutting f...