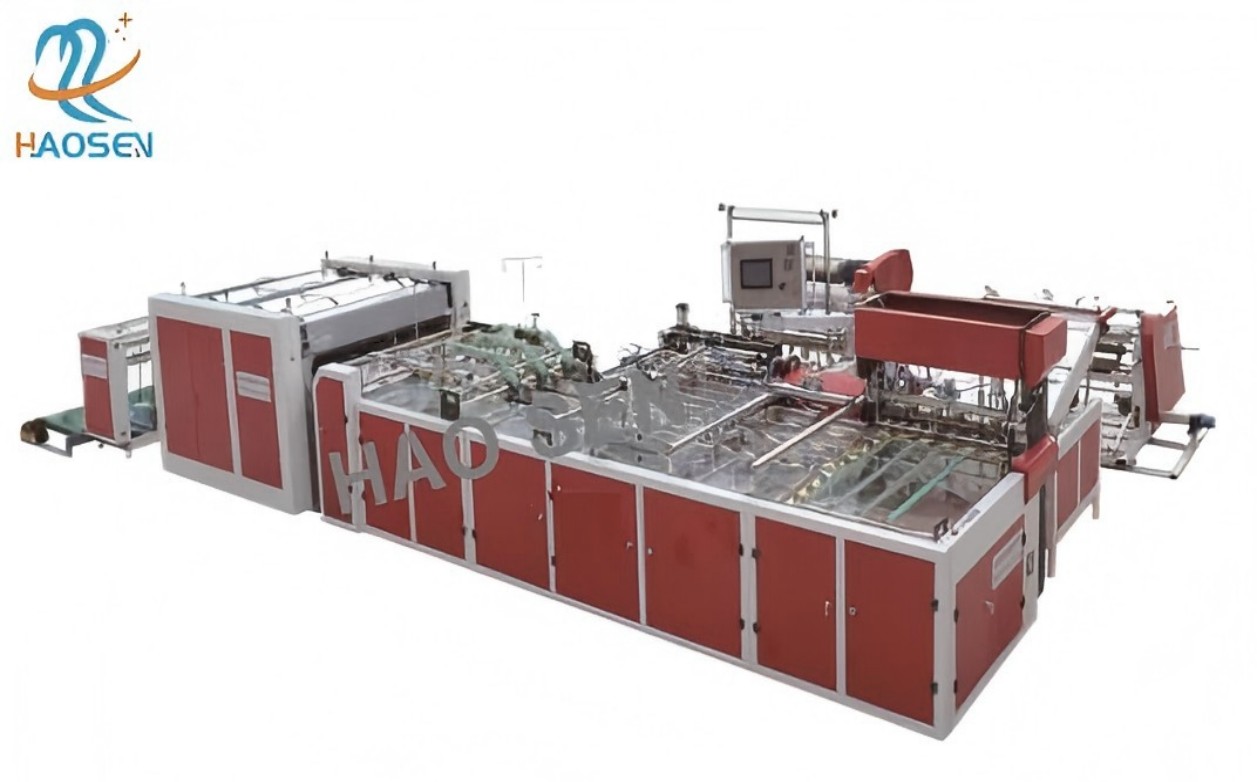

Optional Functions Of OPP/BOPP Bag Making Machine

OPP bags and BOPP bags are common plastic packaging materials, widely used in many industries, resulting in a variety of OPP/BOPP bags. Below I will introduce in detail the functions related to OPP/BOPP bag making machine.

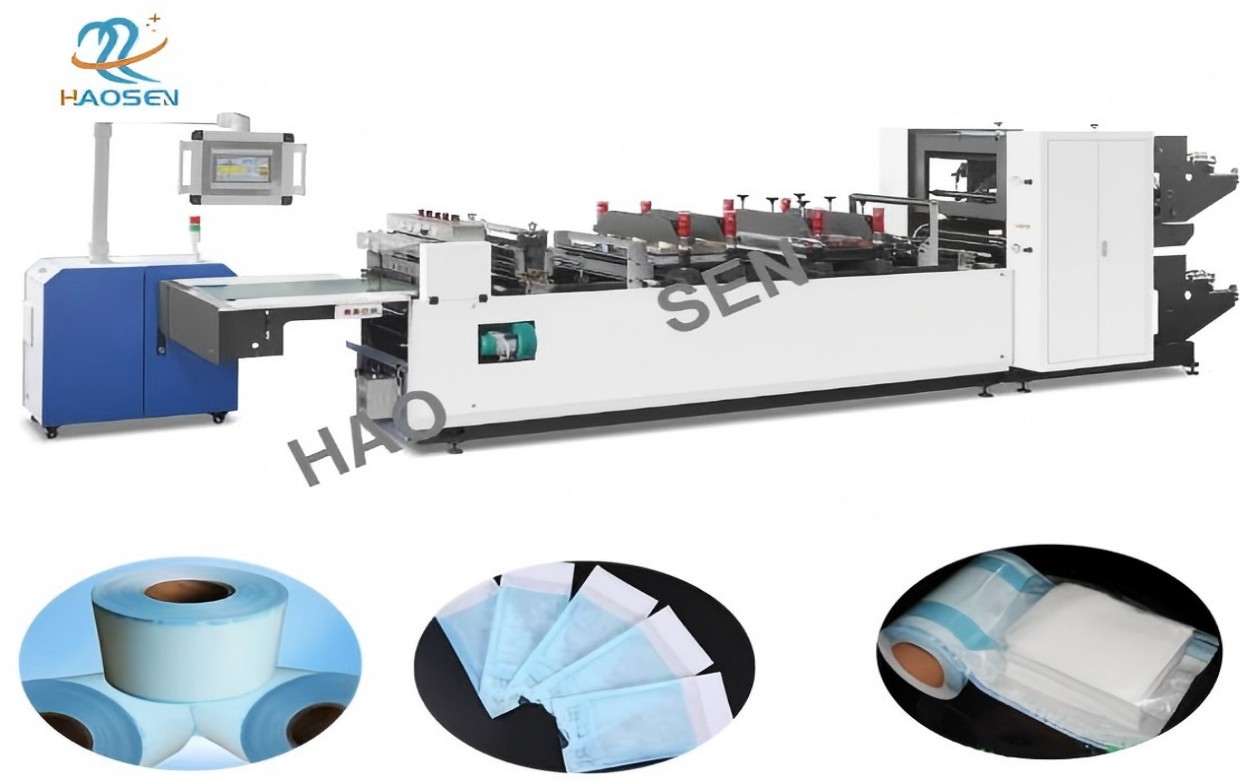

1. Automatic feeding

The machine can automatically feed OPP/BOPP film rolls to ensure continuous production.

2. Cutting function

Plain Edge Cutting: Produce bags with straight edges.

Dot Edge Cutting: Produce bags with dot decorations on the edges.

Double Cutting: One side of the knife has a

flat edge, and the other side has a dot edge. It can be replaced without disassembling the cutting knife.

3. Self-adhesive strip addition

The machine can automatically add self-adhesive strips to the bag mouth for easy sealing and reuse.

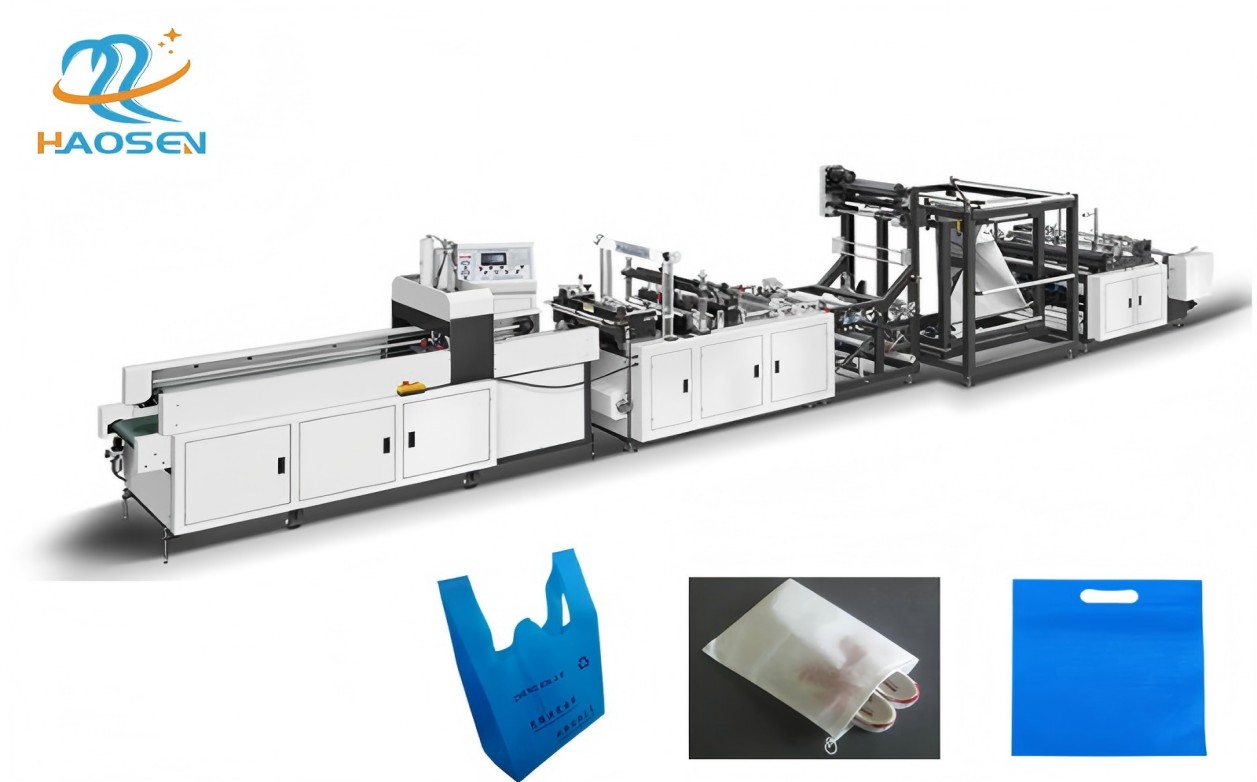

4. Handle hole making

The machine can make handle holes on the top of the bag, usually using ultrasonic sealing technology to ensure the firmness of the handle holes.

5. Ultrasonic sealing

Use ultrasonic technology to seal the bag to ensure a firm and beautiful seal.

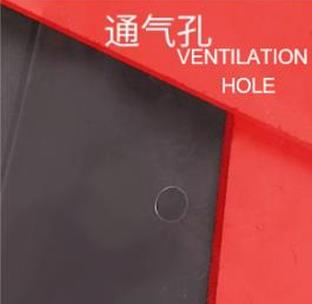

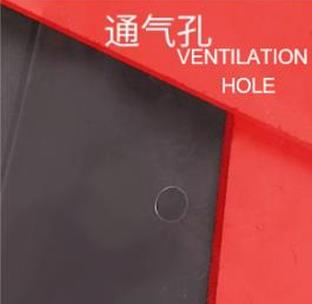

6. Ventilation hole production

The machine can make ventilation holes on the bag, and the number and position can be customized according to customer needs.

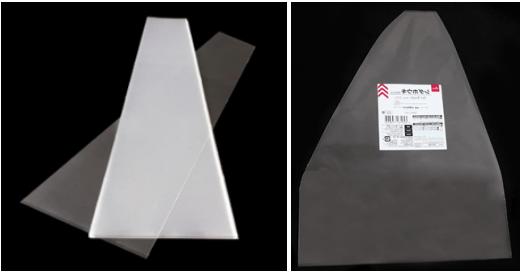

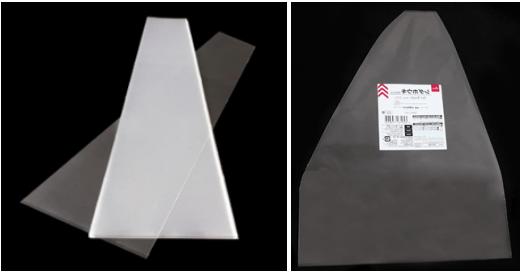

7. Color bag production

The machine can use colored OPP/BOPP film rolls to produce colored bags. The color depends on the roll itself. The machine does not have a printing function.

8. Special-shaped bag production

The machine can produce irregular-shaped bags to meet special packaging needs.

9. Automatic counting and stacking

The machine can automatically count the number of bags produced and stack the bags neatly for subsequent packaging and transportation.

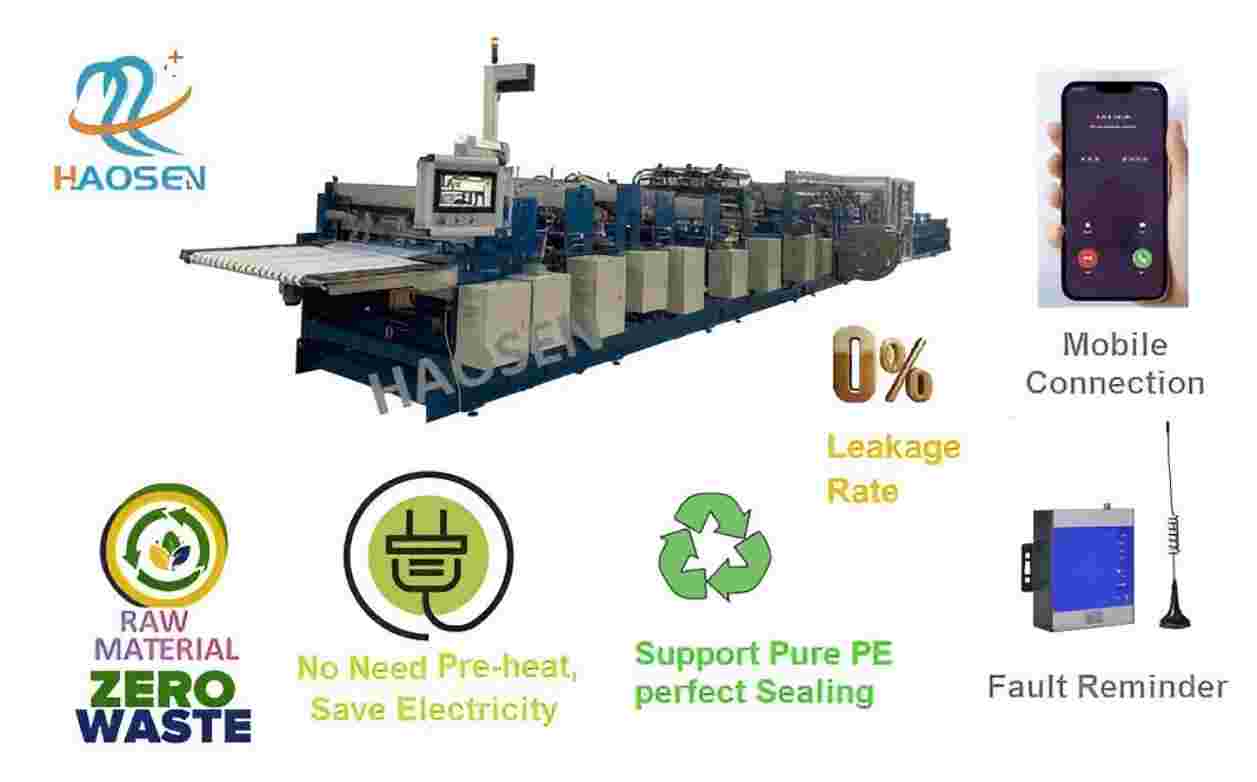

10. Deviation correction device

The deviation correction device can automatically adjust the deviation of the film, and by adjusting the position of the roller or guide device, ensure that the film always runs along the predetermined path, avoid waste caused by deviation, and thus improve product quality.

11. Electronic photoelectric eye

The electronic photoelectric eye can automatically detect the deviation and color error of the film, and correct the error or stop the alarm by controlling the deviation correction device hybrid PLC control system.

12. Adjustable parameters

The various parameters of the machine (such as cutting length, sealing temperature, speed, etc.) can be adjusted according to production needs to ensure that bags that meet the requirements are produced.

13. High efficiency and energy saving

Modern OPP/BOPP bag making machines are usually designed to be highly efficient and energy-saving, reducing energy consumption and production costs.

14. User-friendly interface

The machine is usually equipped with a touch screen control interface, which is easy to operate and convenient for workers to quickly get started and adjust parameters.

These functions enable OPP/BOPP bag making machines to efficiently and flexibly produce various types of plastic bags to meet the packaging needs of different customers.