Production Process of Hemming Inner-Lined Woven Bags

A woven bag with an Hemming inner liner is a packaging product that adds an inner bag design to the standard woven bag, primarily used for occasions requiring item separation or protection. The bag structure is as follows:

Outer layer: Typically woven from polypropylene (PP) or polyethylene (PE), offering features such as wear resistance and tensile strength.

Inner bag: Located inside the outer layer, usually made of plastic film, providing moisture-proof and leak-proof functions.

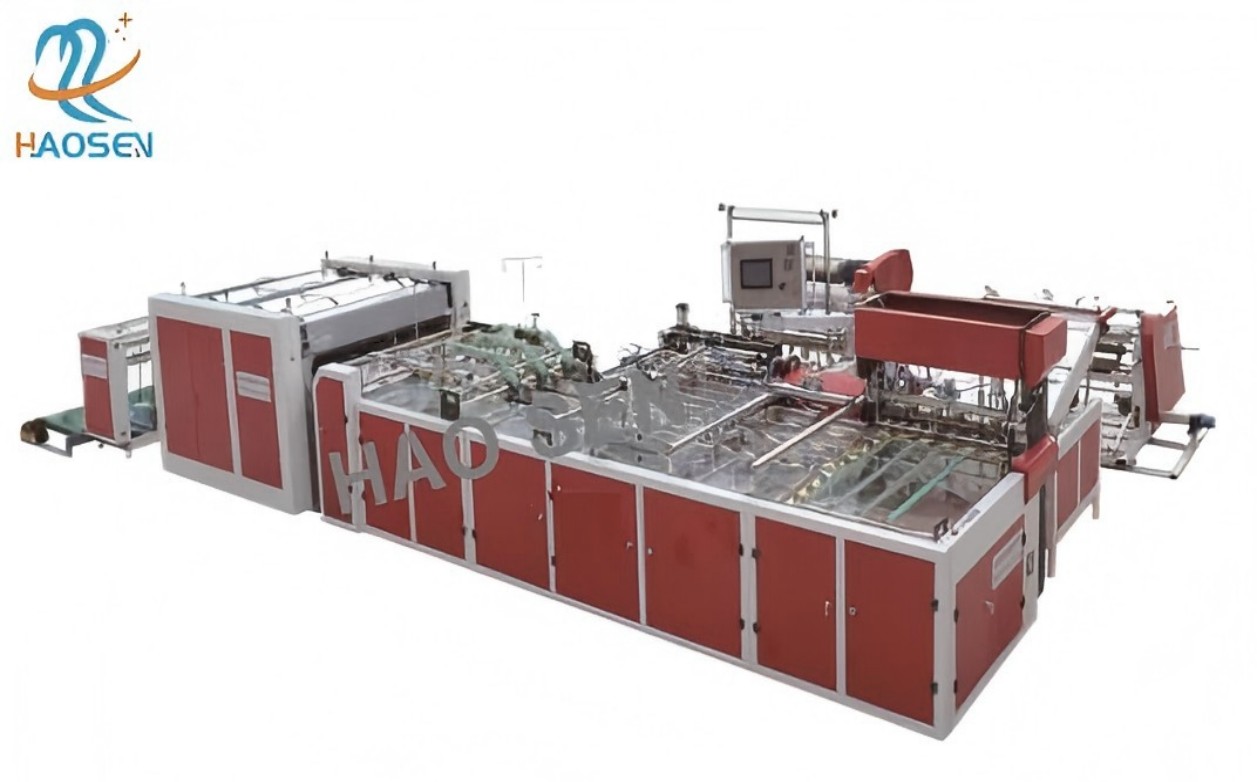

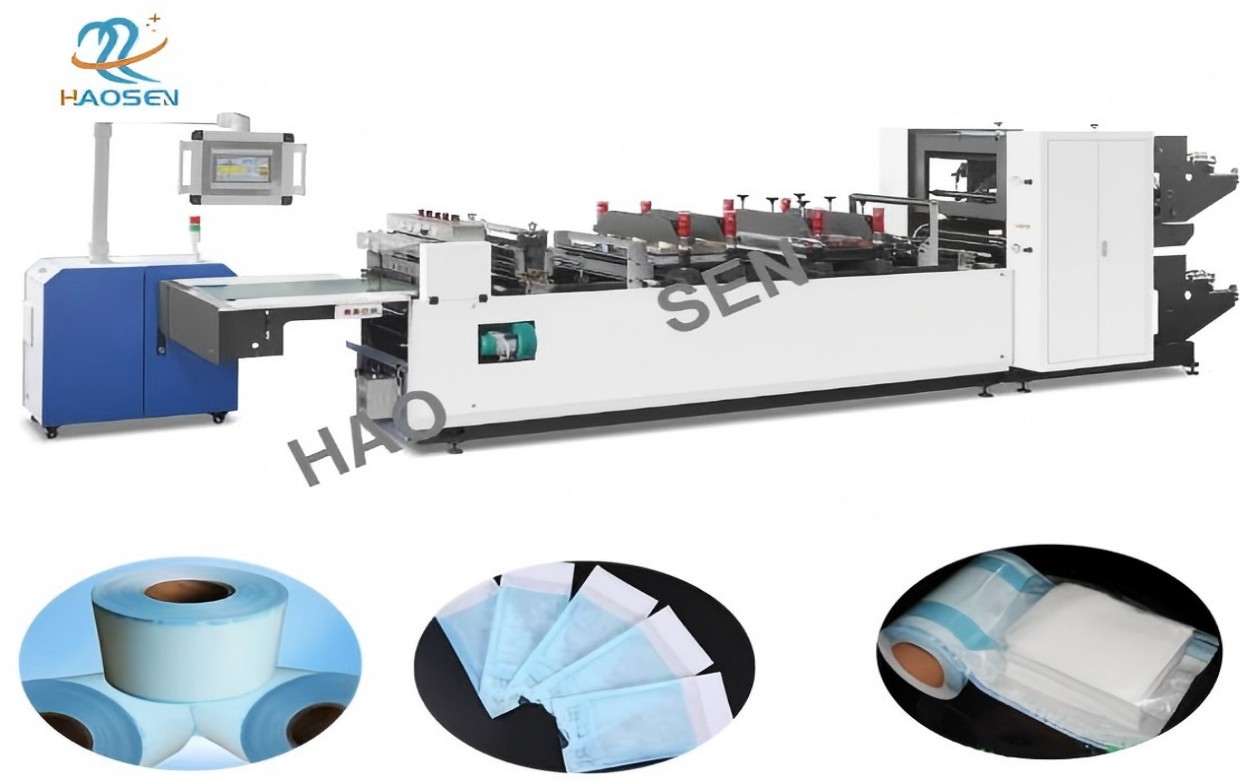

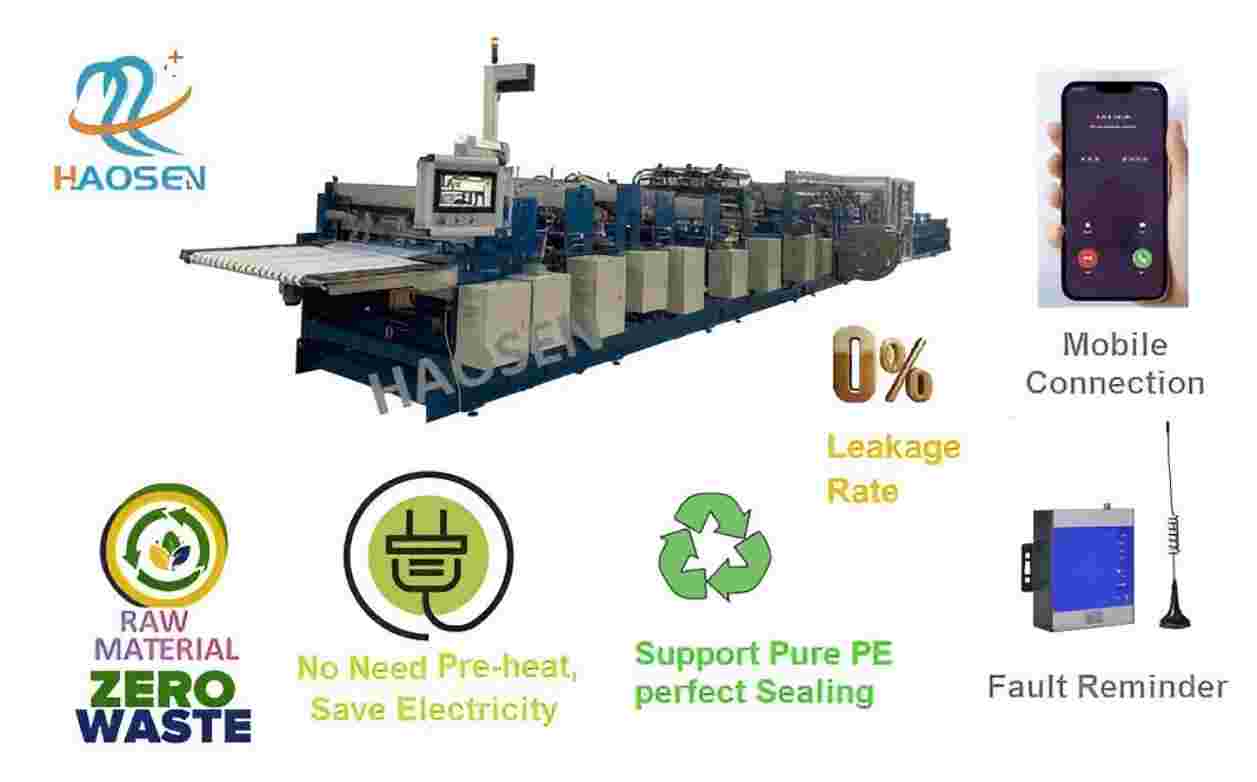

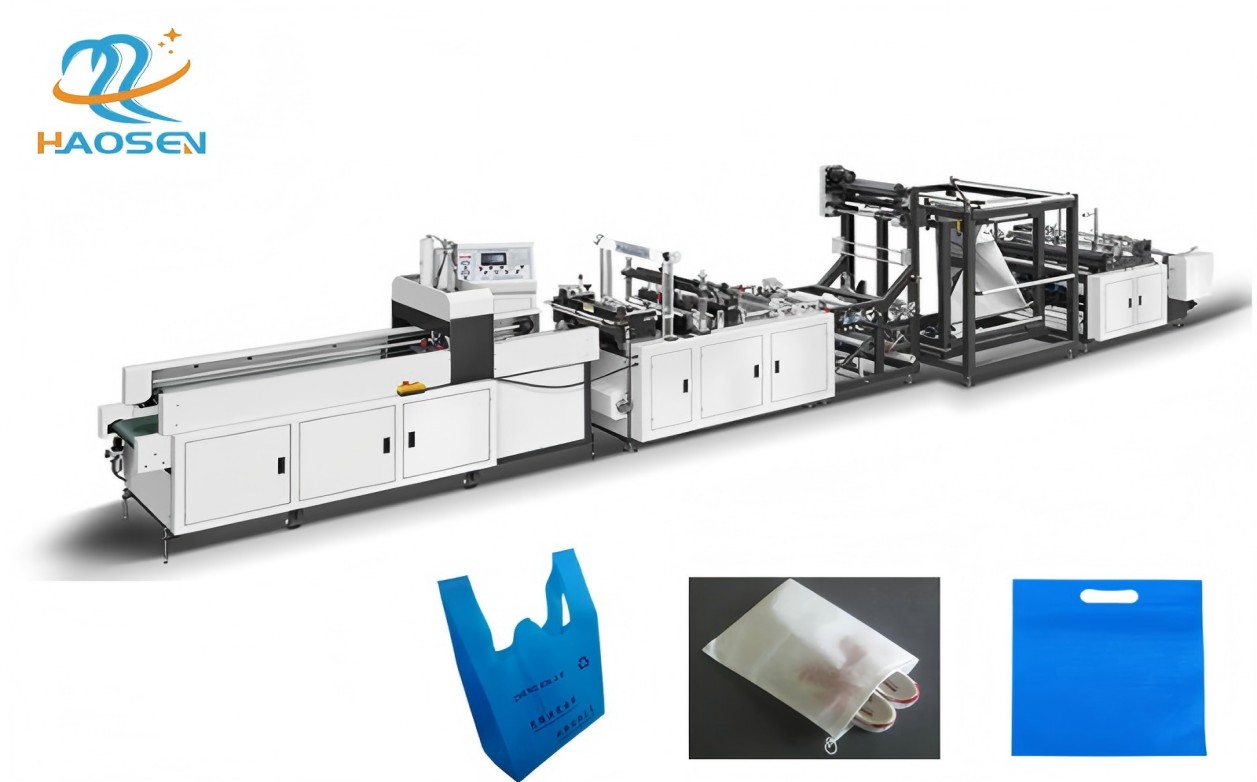

The following diagram shows the production flow chart and product image of a laminated woven bag:

1. Drying and Mixing Machine: PP plastic pellets are fed into a drying mixer for uniform mixing and drying. The mixer is connected to the feed inlet of the filament drawing machine, directly supplying the prepared PP pellets.

2. Flat Wire Extrusion Machine: The PP pellets are melted, extruded, cooled, and shaped into PP Wire via the Extrusion machine. The PP Wire are then wound into Roll by a winding device at the extrusion machine`s end.

3. Circular Loom Machine: The PP Wire Roll are woven into PP woven rolls using a circular loom machine.

4. Film Blowing Machine (inner bag-making machine): PP plastic pellets are fed into a film blowing machine (inner bag-making machine) for mixing and melting. A specialized die head blows out tubular PP plastic film, which is then wound into PP inner bag rolls by a receiving shaft.

5. Printing Machine: The Outer PP rolls are printed with designs or colors using a printing machine.

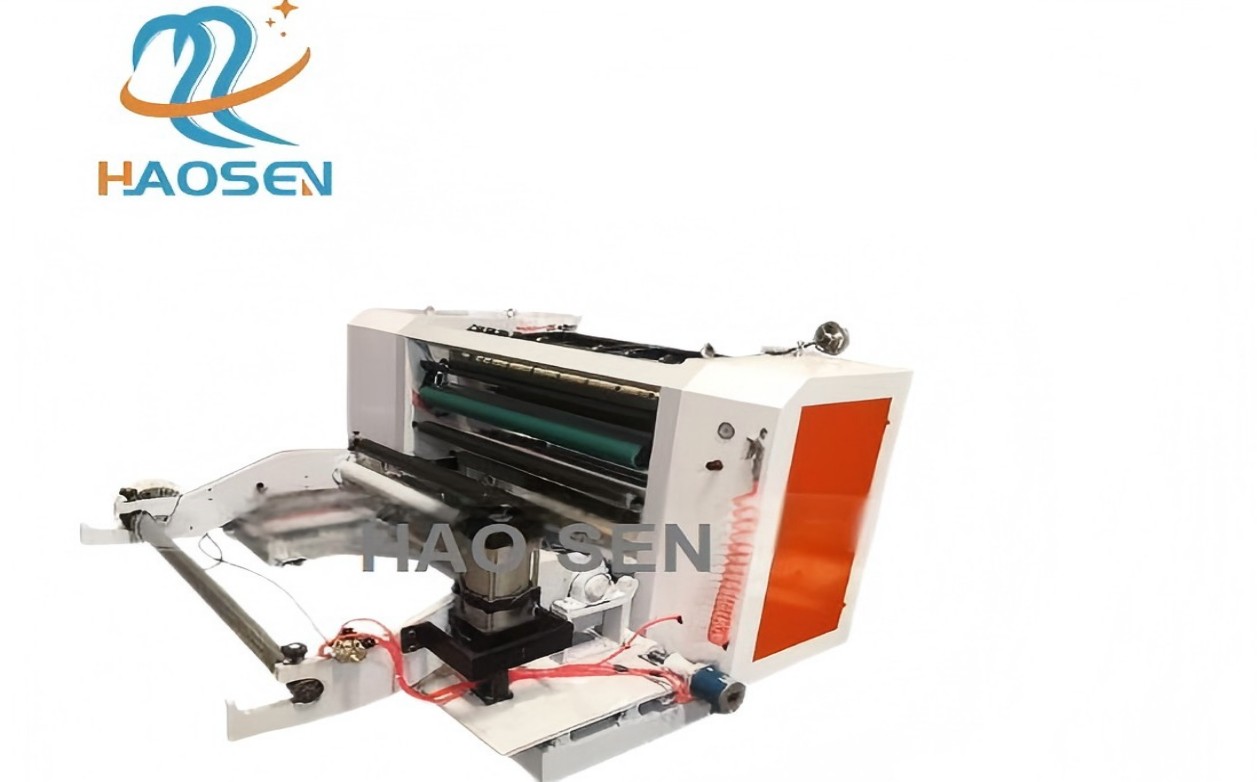

6. The polypropylene outer and inner bag rolls are manufactured into PP bags via an integrated cutting-inserting-sewing-hemming system, executing sequential operations of material sectioning, inner/outer bag nesting, stitch bonding, and circumferential edge finishing.

Applications: Store foods or goods that need to be moisture-proof, such as flour, sugar, etc.

With their functional versatility, cost-effectiveness, and eco-friendliness (some materials are recyclable), inner-lined woven bags have become a core packaging solution for industrial, agricultural, and logistics sectors.