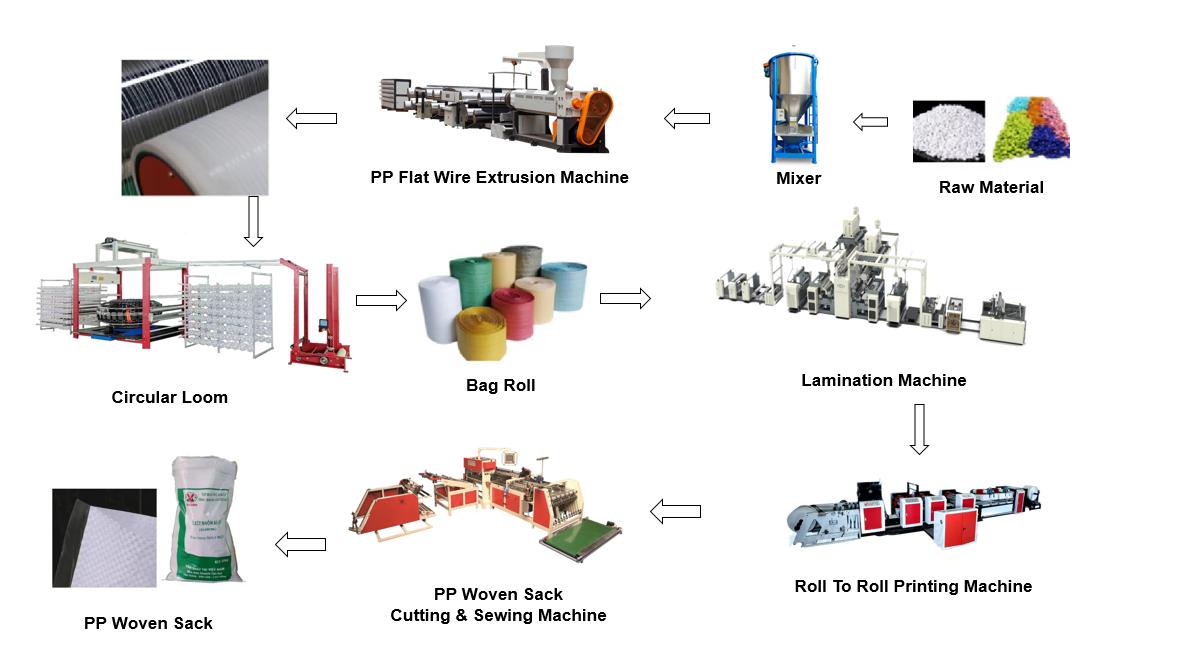

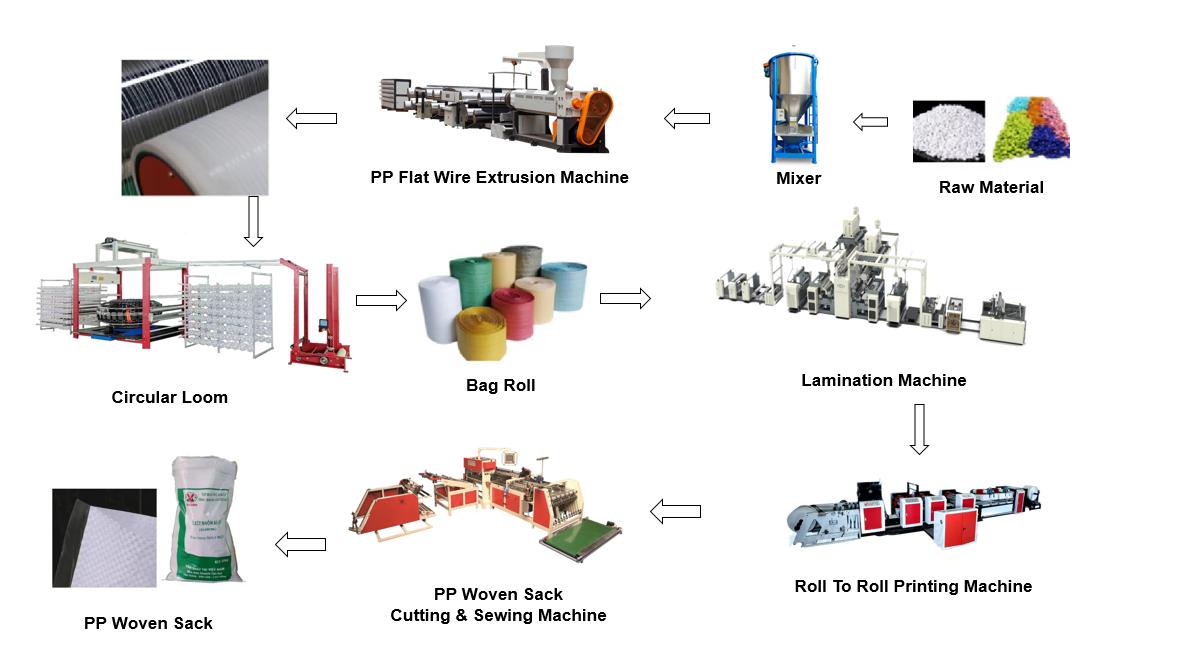

Production Process of Laminated Woven Bags

Laminated woven bags are composite packaging materials made by applying a plastic film (e.g., polyethylene PE, polypropylene PP) onto woven fabric through a lamination process. These bags combine the load-bearing strength of woven fabric with the moisture resistance, waterproofing, and dust proof properties of the laminated film. Below is the production flowchart for laminated woven bags:

1. Drying and Mixing Machine: PP plastic pellets are fed into a drying mixer for uniform mixing and drying. The mixer is connected to the feed inlet of the filament drawing machine, directly supplying the prepared PP pellets.

2. Flat Wire Extrusion Machine: The PP pellets are melted, extruded, cooled, and shaped into PP Wire via the Extrusion machine. The PP Wire are then wound into Roll by a winding device at the extrusion machine`s end.

3. Circular Loom Machine: The PP Wire Roll are woven into PP woven rolls using a circular loom machine.

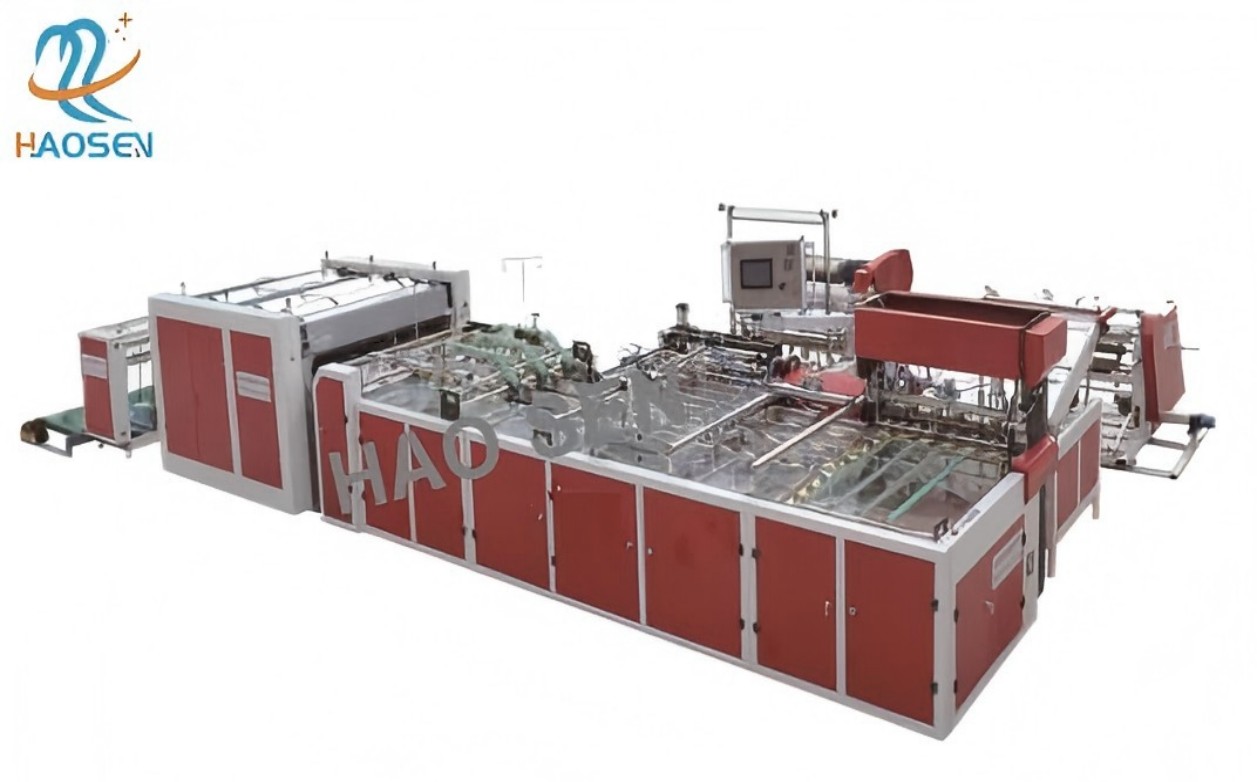

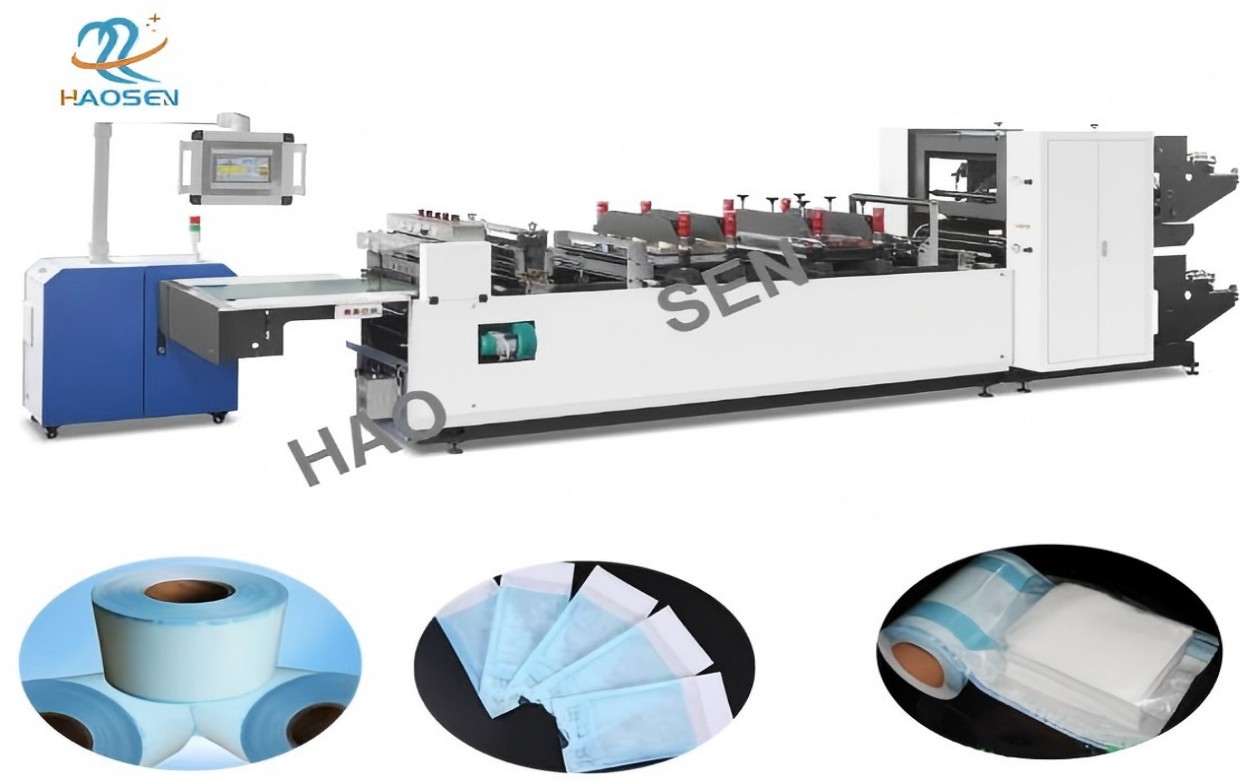

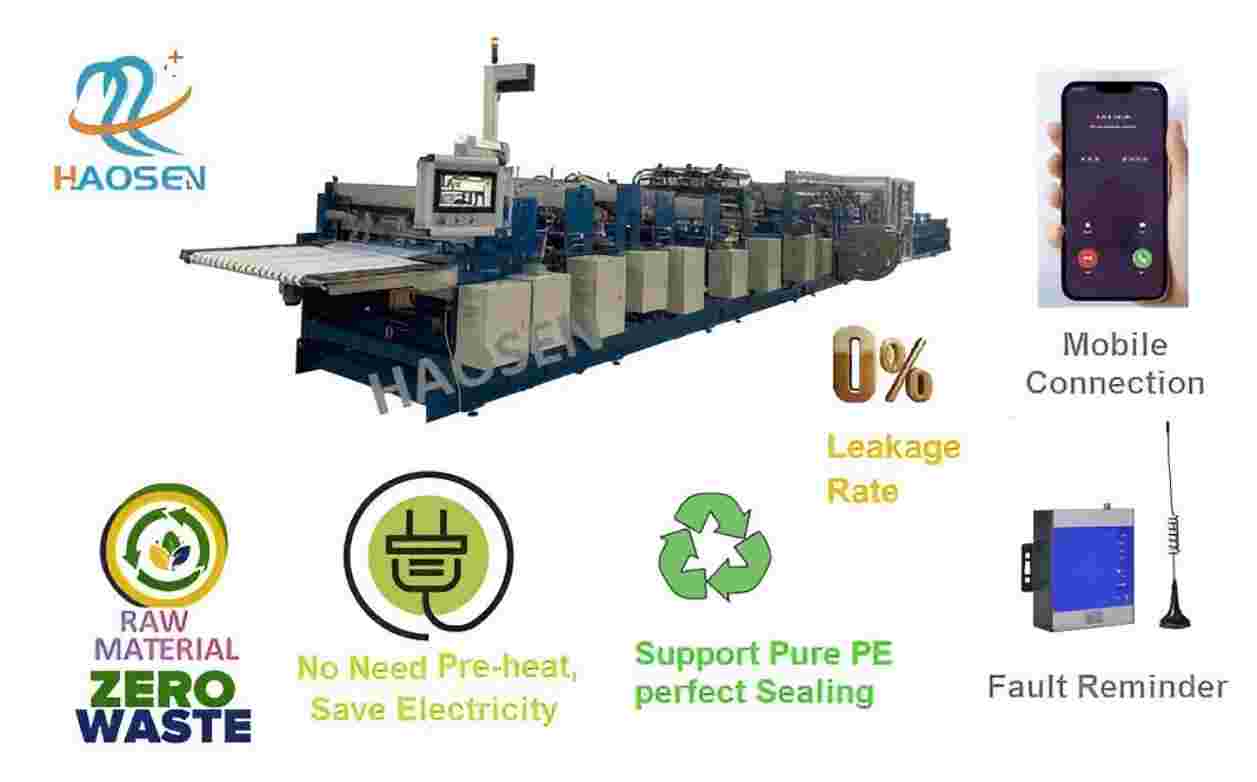

4. Lamination Machine: The PP woven fabric rolls are laminated using a coating machine to produce PP laminated rolls. Two lamination methods are available:

1) Transparent Lamination: A clear film is directly coated onto the PP woven roll.

2) Colored Lamination: A pre-prepared colored film is laminated onto the PP woven roll (higher cost, superior quality, and more vibrant colors compared to print machine).

5. Printing Machine: The laminated PP rolls are printed with designs or colors using a printing machine.

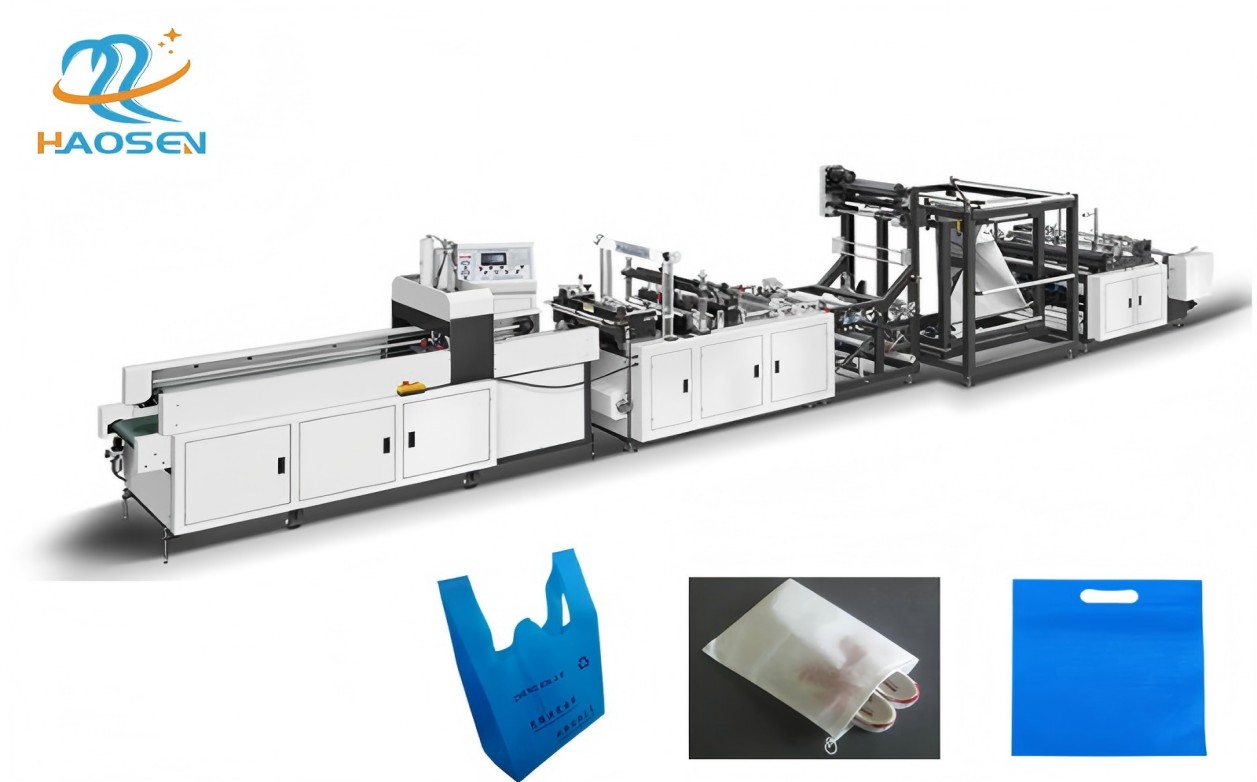

6. Cutting Sewing Machine: The laminated bag rolls are cut and sewn into finished laminated PP woven bags.

Applications: Fertilizers, animal feed, dry goods (e.g., legumes, grains, rice), tea, coffee beans, seeds, agricultural products, laundry detergent, cleaning agents, cosmetic raw materials, and other powdered or granular materials.

Laminated woven bags, with their functionality, cost-effectiveness, and eco-friendliness, have become a core packaging solution in industries such as agriculture, logistics, and manufacturing.