"Degradable express bags are produced using PLA / PBAT, which can be completely degraded in the natural environment, or can be thrown into kitchen waste and completely degraded after being landfilled." Is this the case? Below we analyze this in depth.

The first generation of biodegradable plastic was made by adding starch and photosensitizer to PE (polyethylene).

This plastic bag will gradually disintegrate under sunlight. The starch in the plastic bag is naturally degraded, and the PE cannot be degraded and remains as debris. In the end, the environmental pollution of the plastic bag has only changed from the whole bag to fragmentation.

The second-generation biodegradable plastic is the PLA / PBAT plastic bag that e-commerce is currently admiring.

PLA is a bio-based degradable material whose raw material comes from the starch of corn or cassava crops. PBAT is a petroleum-based degradable material ,its raw materials are extracted from petroleum.

Because PLA has the disadvantage of high brittleness, and PBAT has good toughness, many manufacturers mix the two materials in proportion to improve the strength and toughness of the composite.

PLA / PBAT plastic bags are buried in the soil, and the actual degradation rate is very slow.

Although PLA is made from plant starch, it is not a natural compound in nature, and it is significantly different from natural degradable materials.

After chemical polymerization, PLA itself is not easy to be directly degraded by microorganisms, enzymes, etc , before being biodegraded, it needs to undergo a hydrolysis process.

PLA is a non-hydrophilic substance with a dense surface structure, making it difficult for water to enter its interior. In existing scientific experiments, PLA samples were buried in the soil for one year, and the mass loss was only 0.23%. ①

PBAT is derived from petroleum and can not be directly degraded. It must be hydrolyzed first. (Some researchers have buried pure PBAT samples in the soil in an attempt to degrade them, but no significant changes have occurred at 155 days. ②)

After PLA / PBAT copolymer enters the soil, the degradation rate is also very slow, the reason is consistent with the above situation. In the natural soil environment, the conditions for PLA / PBAT to hydrolyze in advance are lacking, and subsequent degradation is impossible to talk about. ③

PLA / PBAT plastic bags degrade slowly in the marine environment.

In June 2017, Amir Reza Bagheri of the University of Bayreuth, Germany published a paper, immersing PLA and PBAT samples in seawater and fresh water at 25 ℃ under natural light for one year, and conducted experimental observations. It was found that PLA and PBAT samples were not substantially degraded, and the hydrolysis rate was <2%. ④

From the known information, only in the composting environment that meets the conditions, PLA / PBAT can achieve rapid degradation-about 60% degradation in 30 days. These conditions must include: adequate humidity, a certain aeration rate, high temperatures, and the use of rotting compost as inoculum. ⑤

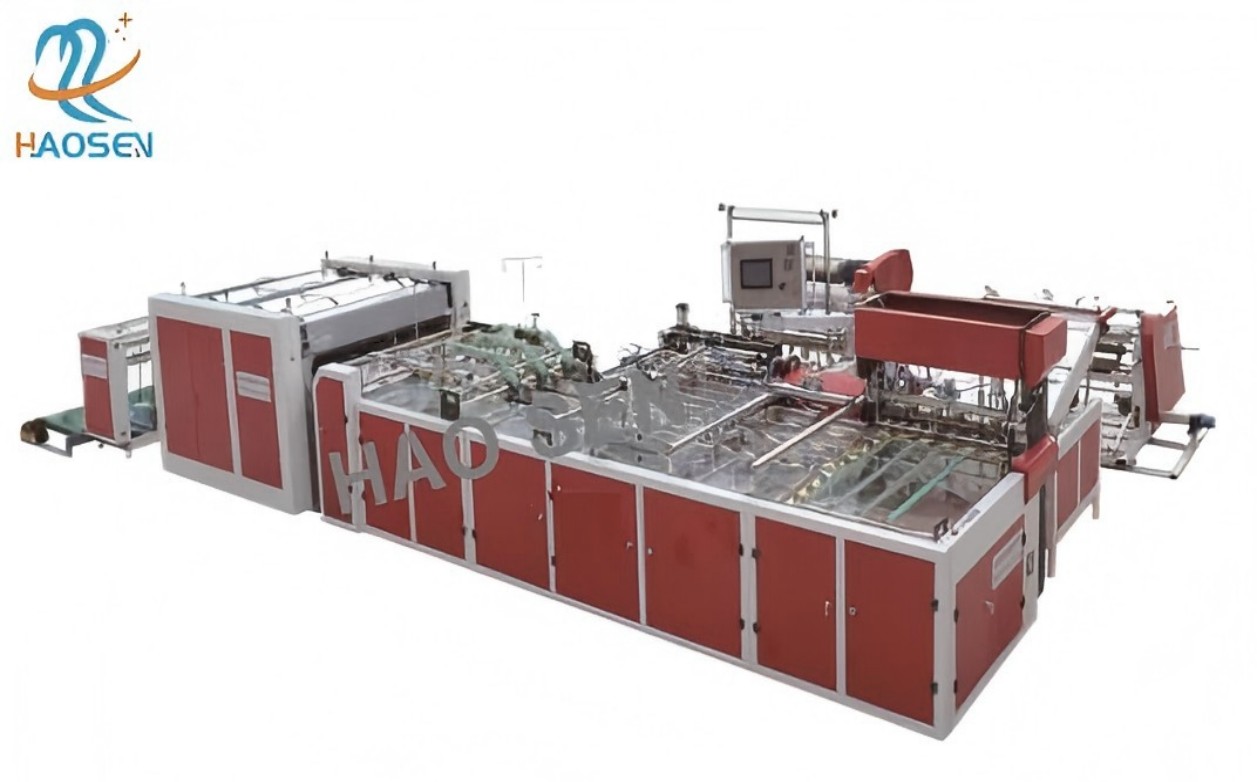

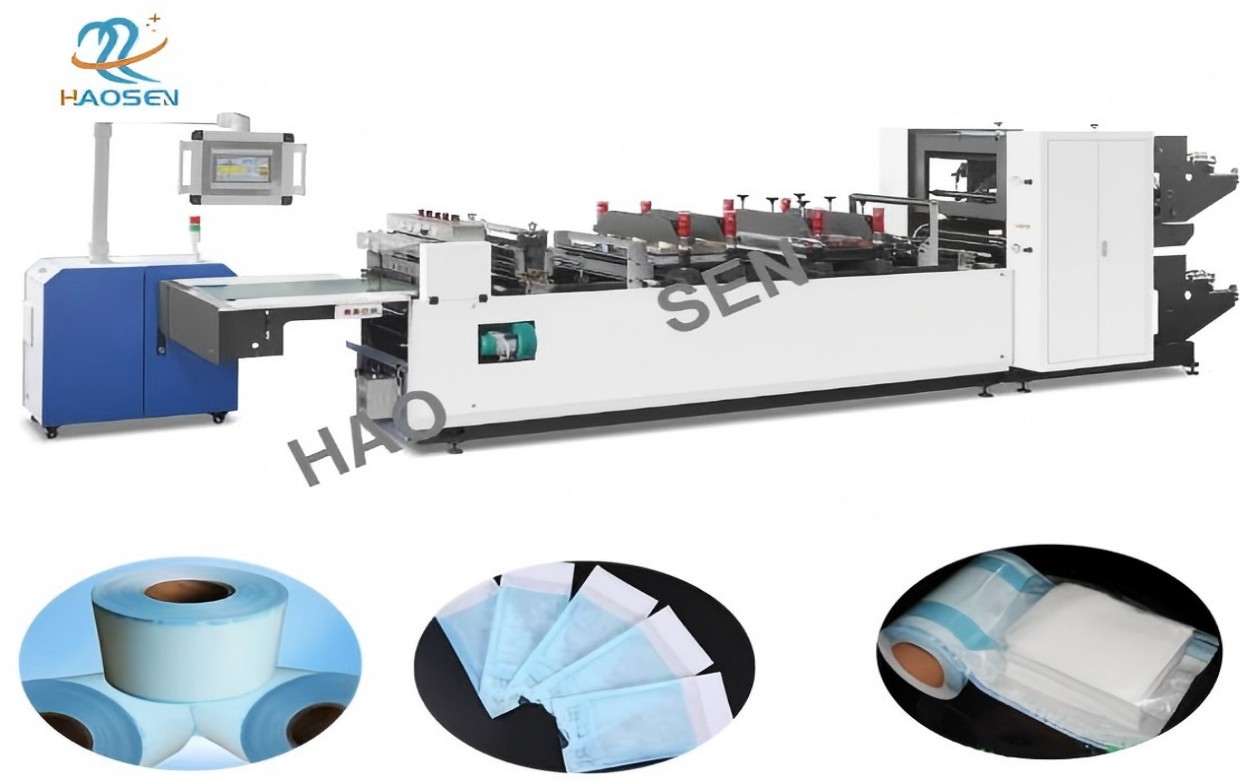

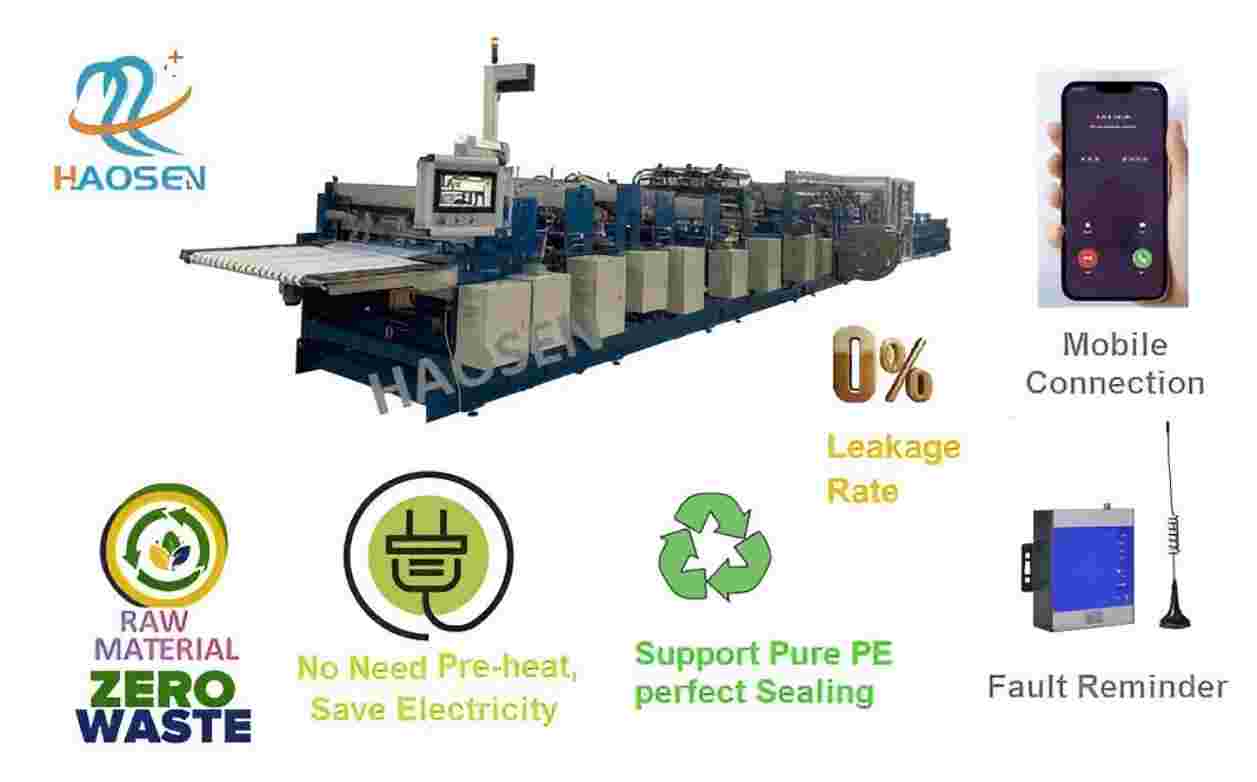

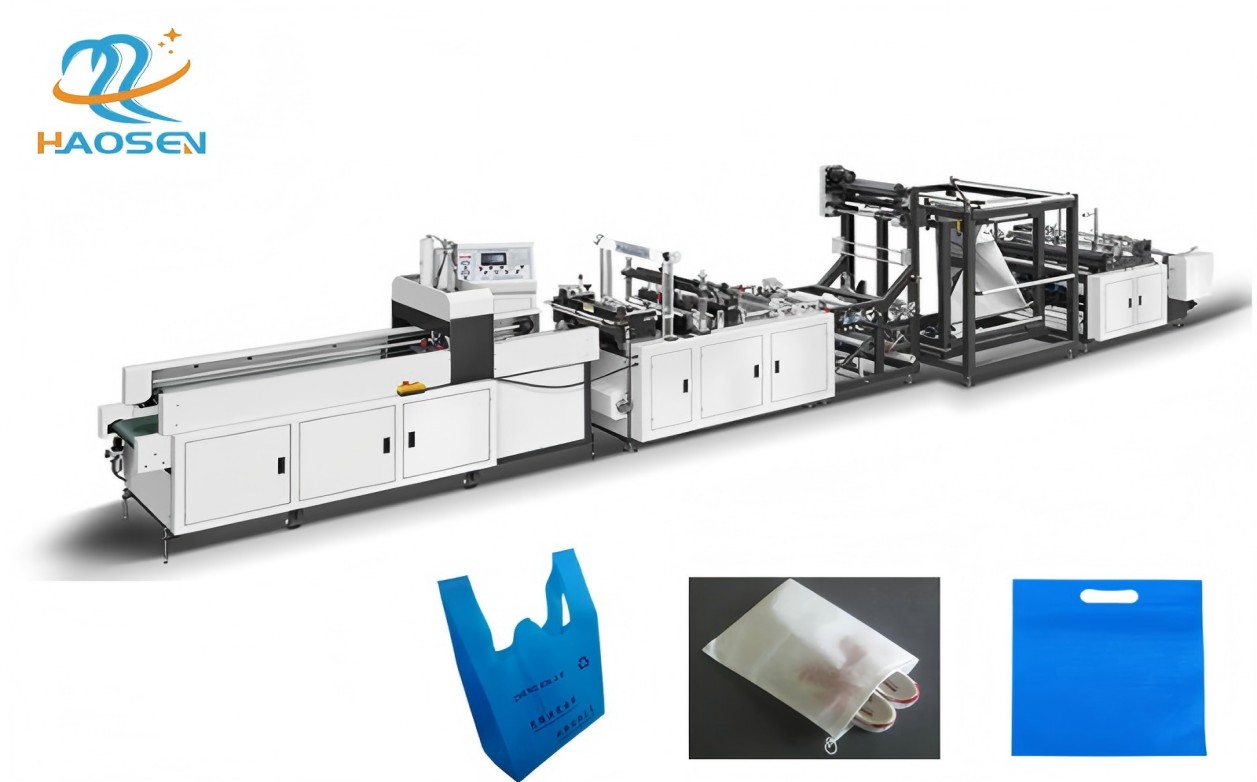

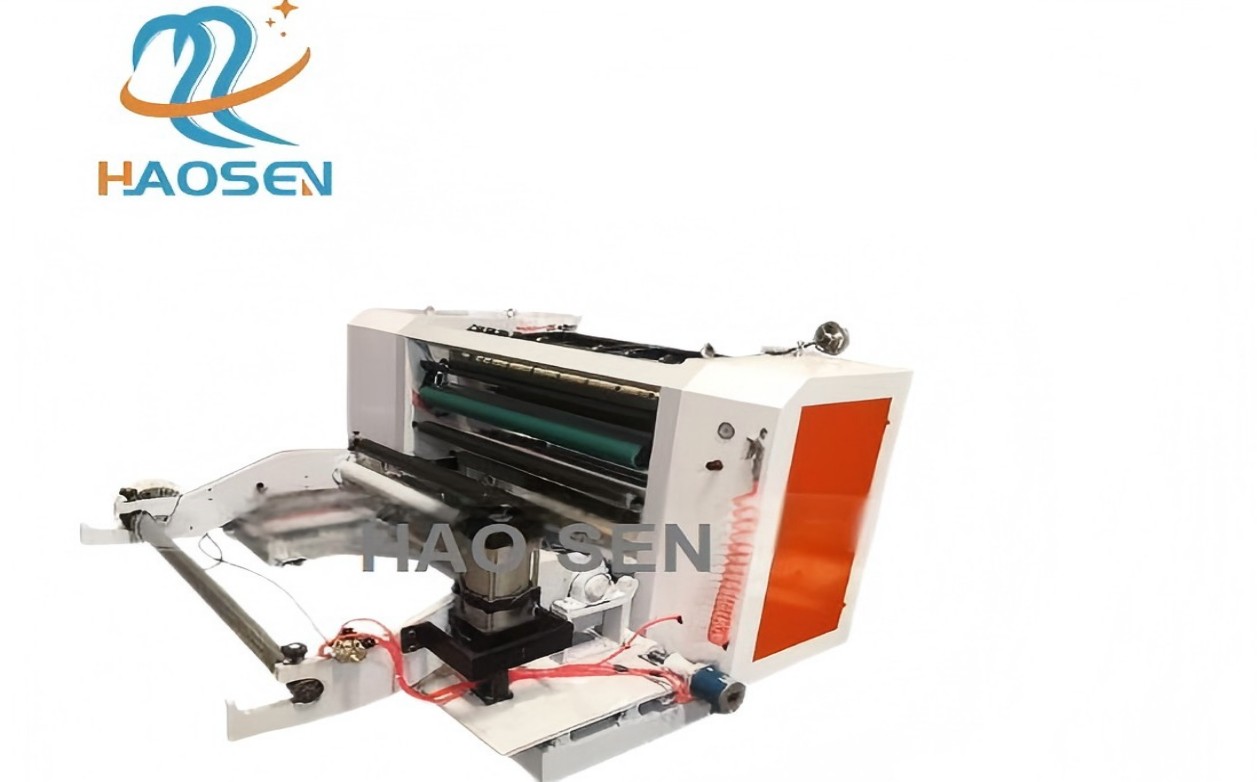

For a good environment, pls use new type ECO friendly bag making machine from Haosen.

Literature source:

① Zheng Xia, Li Xingong, Wu Yiqiang: "The Natural Degradability of Polylactic Acid", "Functional Materials", No. 14 of 2014.

② Zhou Chengwei, Zhang Yu, Wu Zhihua: "Research on the Degradability of PBAT in Filled Composites", "Plastics Science and Technology", September 2013 Vol.41 No.9.

③ Si Peng, Hao Niyuan, Liu Yang, etc .: “Preparation of PLA / PBAT film and its degradation performance”, “Biological and Degradable Materials”, October 2015

Volume 43 Number 10.

④ Amir Reza Bagheri, Christian Laforsch etc .: "Fate of So-Called Biodegradable Polymers in Seawater

and Freshwater, Global Challenges, July 14, 2017, Volume 1, Issue 4.

⑤ Zhang Min, Meng Qingyang, Diao Xiaoqian, and Weng Yunxuan: “Degradability of PLA / PBAT Blends”, China Plastics, Volume 30, Issue 8, August 2016