PP woven bag production line equipment related calculations

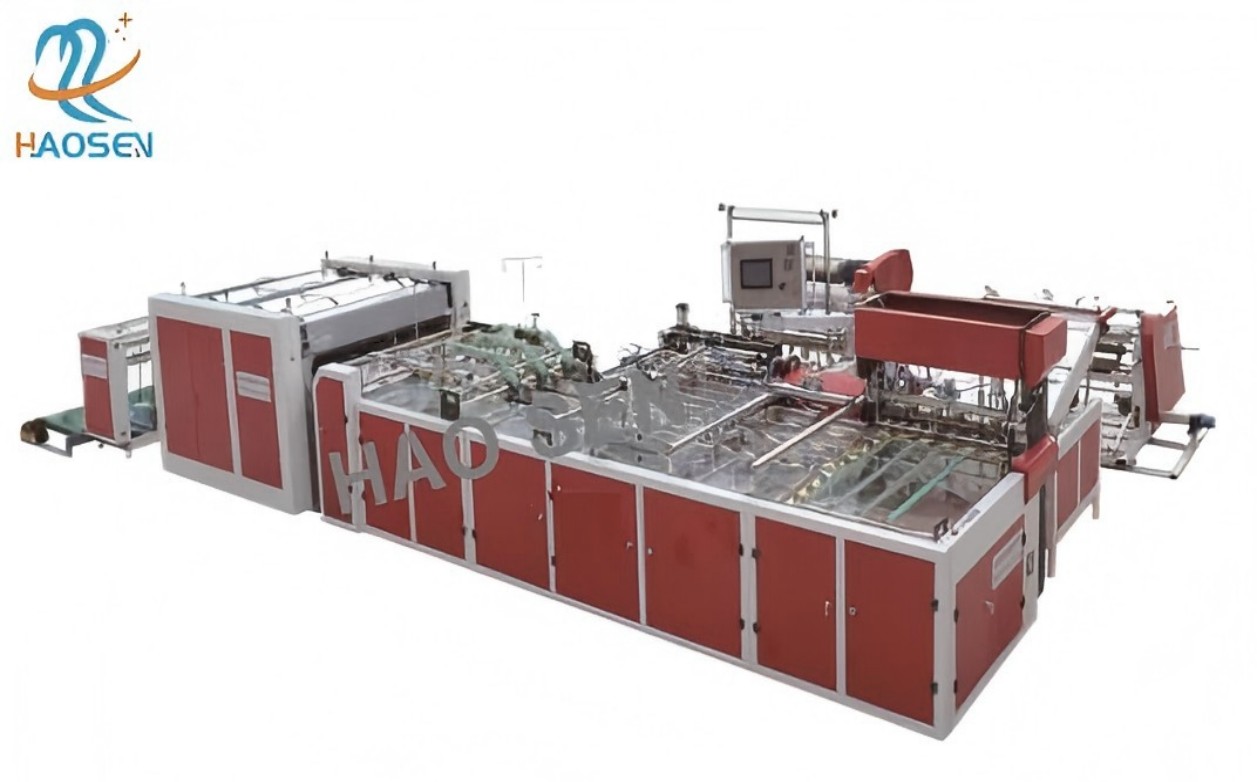

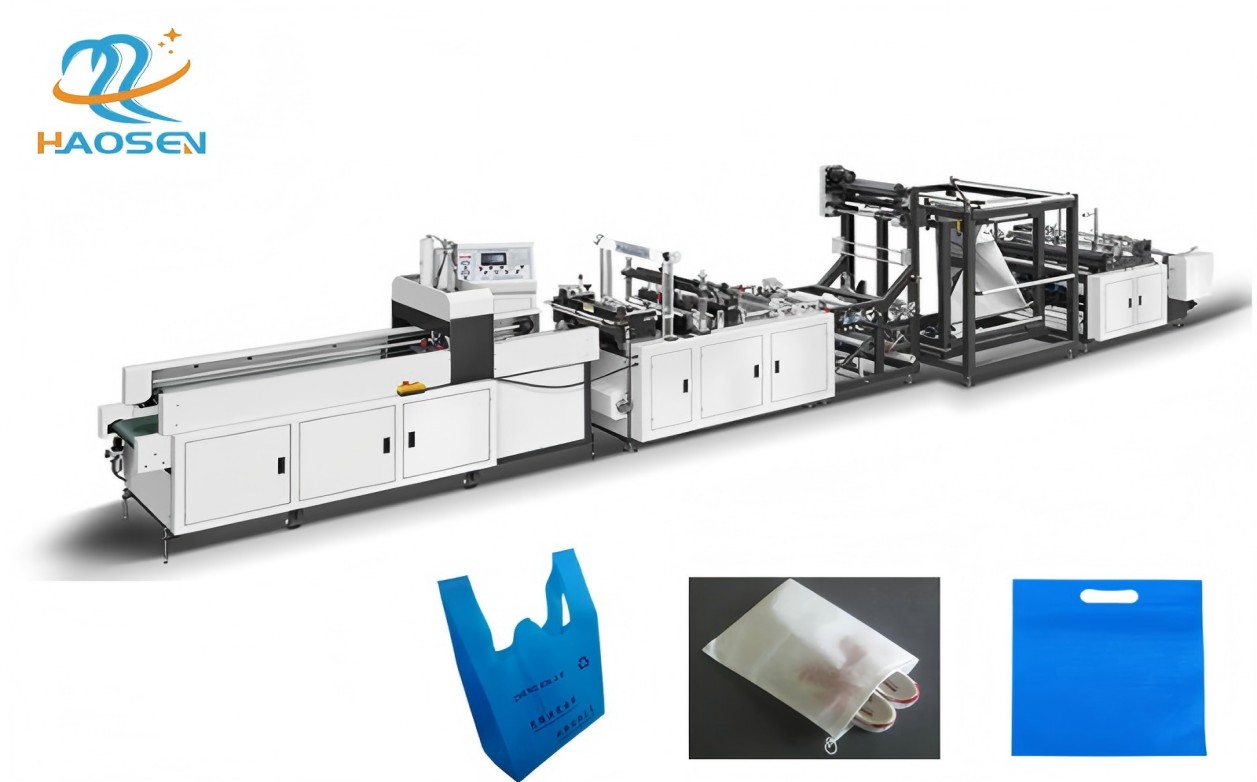

There are two different production methods for making PP woven bags. One is to start the production from PP granule, through drawing-round weaving-filming-printing-cutting-sewing and then produce into woven bag, which belongs to the whole production line. The other is to buy the woven fabric rolls directly and produce the woven bags after printing, cutting and sewing. Next I will explain the calculations related to the machines involved in the first production method.

The first is the PP flat wire extrusion machine.

Many customers don't know what capacity PP flat wire extrusion machine to choose. For example, the weight of a bag is 108g, if we produce 120,000 bags a day, we need at least 108*120000=12960kg of raw material. And the PP flat wire extrusion machine must work 24 hours a day, otherwise it will cause a big waste of raw materials, so the output of the PP flat wire extrusion machine needs to reach 12960/24=540kg/h. This way we calculate the approximate output of the PP flat wire extrusion machine.

After knowing how to choose the PP flat wire extrusion machine, the quantity of circular loom also needs to be calculated.

Again for this customer, The length of a bag is 1200mm, so the customer needs to make (1200+50)*120000=150000m per day (50mm is the length consumed by cutting). Each 4-shuttle circular loom works according to 24 hours, the speed is 180r/min, the width of raw material silk is 2.5mm, so each circular loom can weave 24*4*180*60*2.5=2592m of woven fabric rolls in a day. (Here *4 is because the circular loom is a 4-shuttle circular loom, if it is a 6-shuttle or 8-shuttle circular loom, then it needs to be *6/*8; *60 is 1 hour is 60min, and it needs to be a unified unit) So 150000/2592=58 circular looms are required. There is also a need to add 2 extra circular looms as a back-up. So the number of circular looms is 58+2=60 units.

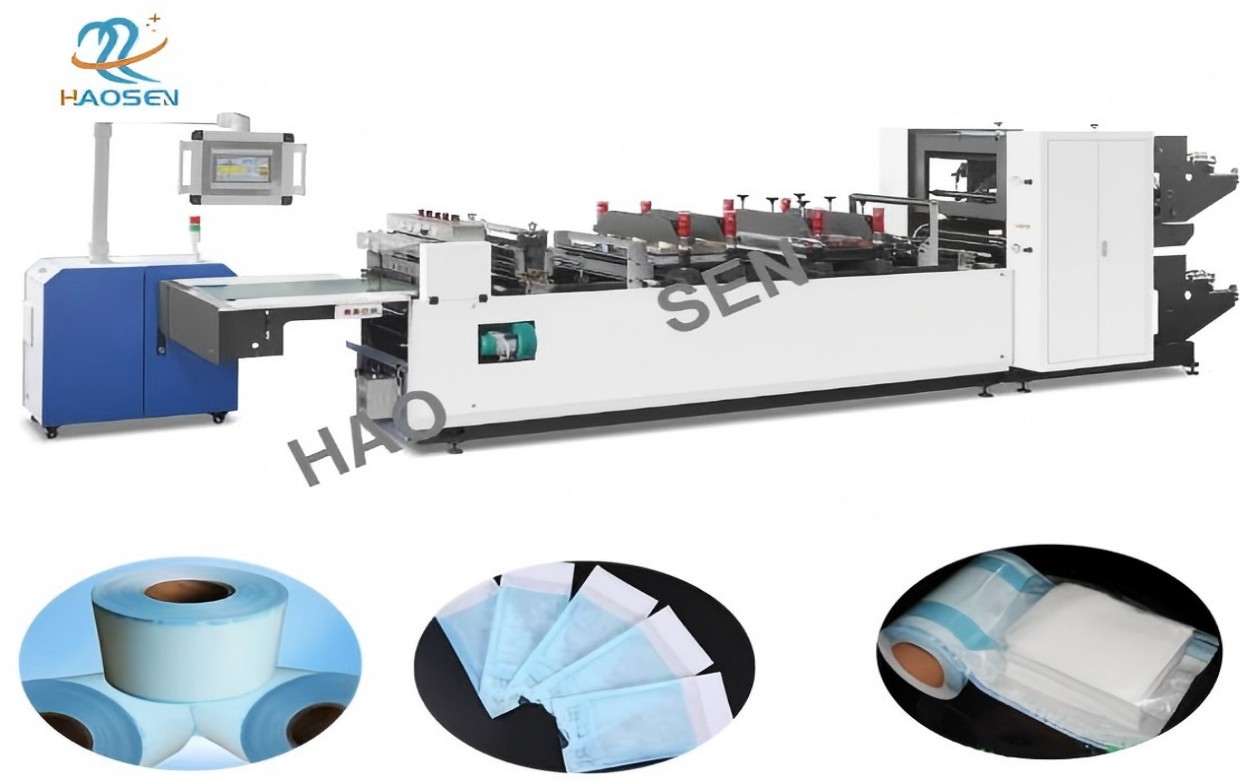

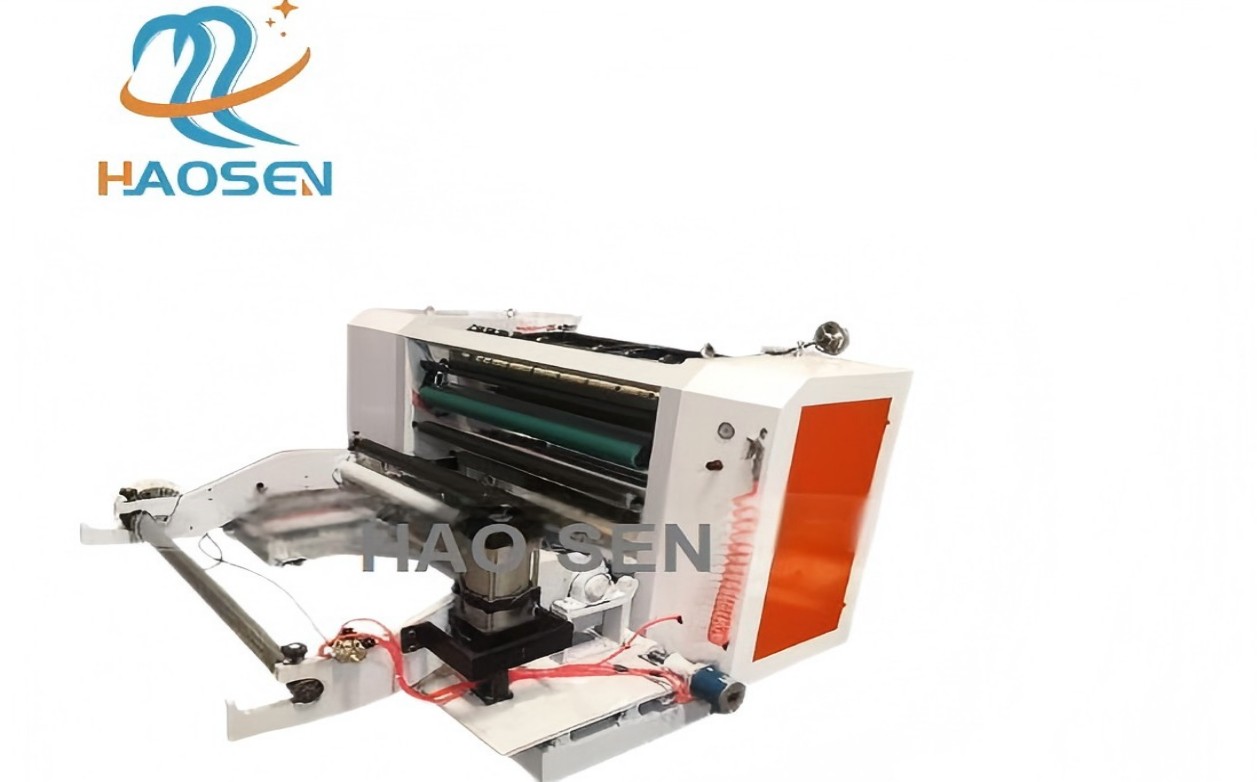

To know how many laminating machines are needed, you only need to know the speed of the laminating machine .

Generally the speed of the laminating machine is 30-230m/min, from which we can calculate that a 24-hour working day is able to laminate 43,200-331,200m (30*60*24=43,200m, 230*60*24=331,200m). Then calculate how many bags can be laminating according to the length of the bag. For the same customer, a bag length is 1200mm, so one laminating machine can laminate 36,000-276,000 bags a day (43200/1.2=36000, 331200/1.2=276000).

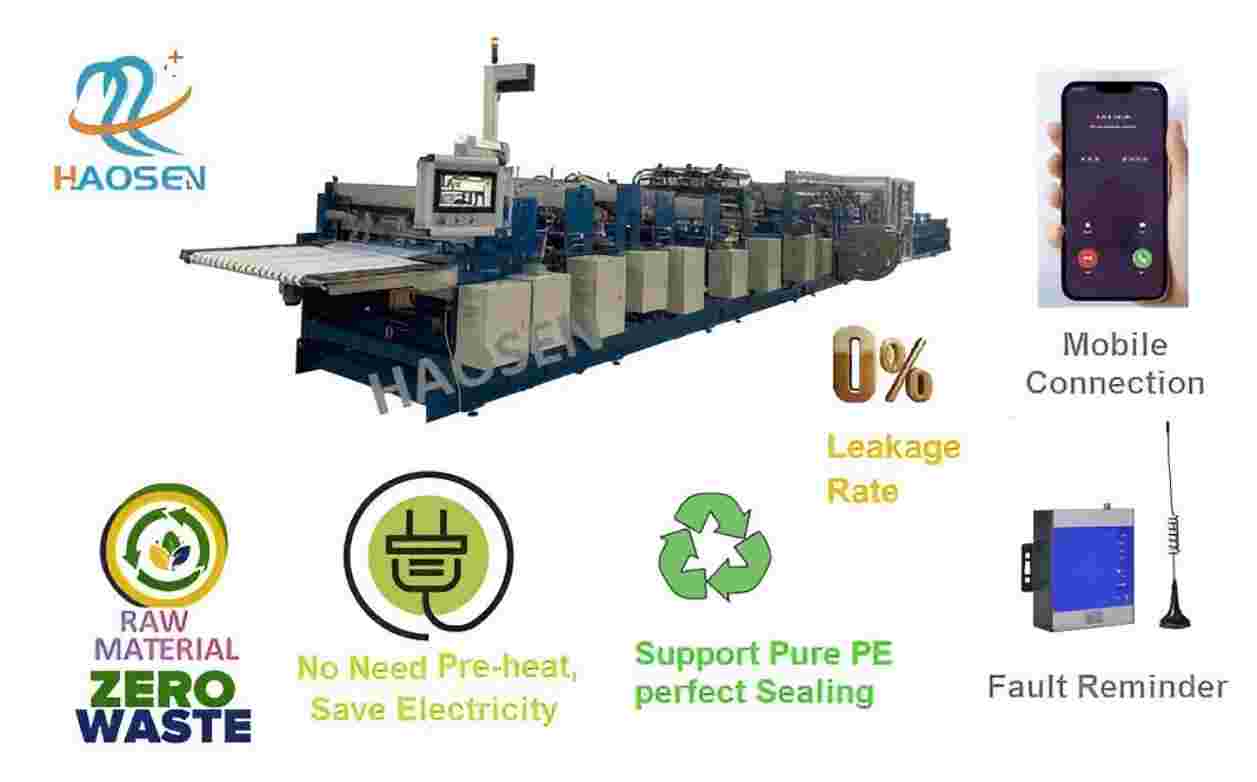

Next is the printing machine. There are two types of printing machines, one is roll-to-roll printing machine,and the other is bag to bag printing machine.

First of all, let's talk about how to calculate how many roll-to-roll printing machines are needed. The speed of a roll-to-roll printing machine is 100m/min, if it works for 20 hours, then a machine can print 100*60*20=120000m a day, so it needs 150000/120000=1.25≈2 printing machines. (150,000m is the total length of the production calculated when we talked about circular loom before) Next, let's talk about the bag-to-bag printing machine. The speed of a bag to bag printing machine is 1500-3000pcs/h, so according to the calculation of working 20 hours per day, a printing machine can make 30,000-60,000 bags per day (1500*20=30000, 3000*20=60000). If the output is 120,000 bags per day, then 2-4 printing machines are needed (120,000/30,000=4, 120,000/60,000=2).

Finally, let's talk about the cutting and sewing machine.

The same calculation idea, first know the machine speed, then calculate the number of bags that can be made per unit of time, according to the customer needs to calculate the number of machines needed. The speed of the cutting and sewing machine is 30-40pcs/min, according to the calculation of 20 hours a day, a machine can make 36,000-48,000 bags per day (30*60*20=36000, 40*60*20=48000). Customer demand is 120,000 bags per day, need to buy 3-4 machines (120,000/36,000=3.33≈4, 120,000/48,000=2.5≈3).

The same calculation idea, first know the machine speed, then calculate the number of bags that can be made per unit of time, according to the customer needs to calculate the number of machines needed. The speed of the cutting and sewing machine is 30-40pcs/min, according to the calculation of 20 hours a day, a machine can make 36,000-48,000 bags per day (30*60*20=36000, 40*60*20=48000). Customer demand is 120,000 bags per day, need to buy 3-4 machines (120,000/36,000=3.33≈4, 120,000/48,000=2.5≈3).

The above calculations are only intended as indicative results to enable customers to have a preliminary understanding.

For details, contact us via WhatsApp: +86 15633821221

You can learn more from:www.hsbagmachinery.com